How does a Hydraulic Windlass work efficiently?

2025.08.15

2025.08.15

Industry News

Industry News

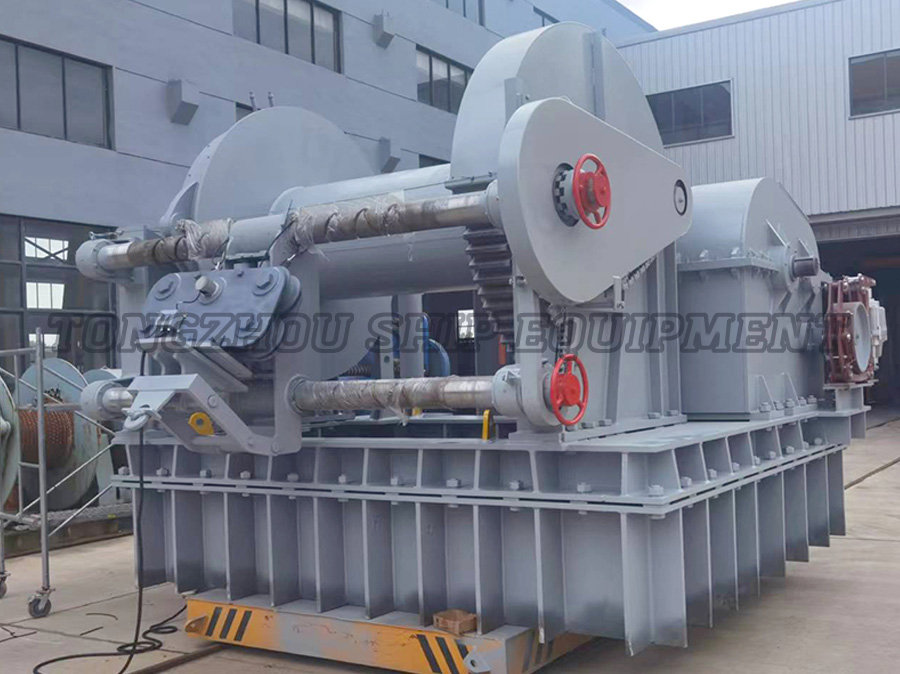

The reliable deployment and retrieval of heavy anchor chain is a critical operation aboard vessels, demanding robust and efficient machinery. The hydraulic windlass stands as the cornerstone of this task. Understanding how it functions efficiently is essential for optimal performance and longevity.

Core Operating Principle: Converting Fluid Power to Mechanical Force

At its heart, a Hydraulic Windlass transforms hydraulic energy into powerful rotational torque for the chainwheel or gypsy head. This process involves several integrated components:

-

Hydraulic Power Source: A hydraulic power unit (HPU), typically located remotely in the machinery space, generates the necessary flow and pressure. This unit consists of:

-

Prime Mover: An electric motor or diesel engine driving the pump.

-

Hydraulic Pump: Converts mechanical energy from the prime mover into hydraulic energy (flow under pressure). Common types include gear pumps, piston pumps, or vane pumps. Pressure-compensated or variable displacement pumps are often employed for efficiency, delivering flow only as demanded.

-

Reservoir: Stores hydraulic fluid and allows for cooling and contaminant settling.

-

Control Valves: Directional control valves (often solenoid-operated from the deck) direct fluid flow to the hydraulic motor for heaving (hoisting) or veering (lowering). Relief valves protect the system from overpressure.

-

-

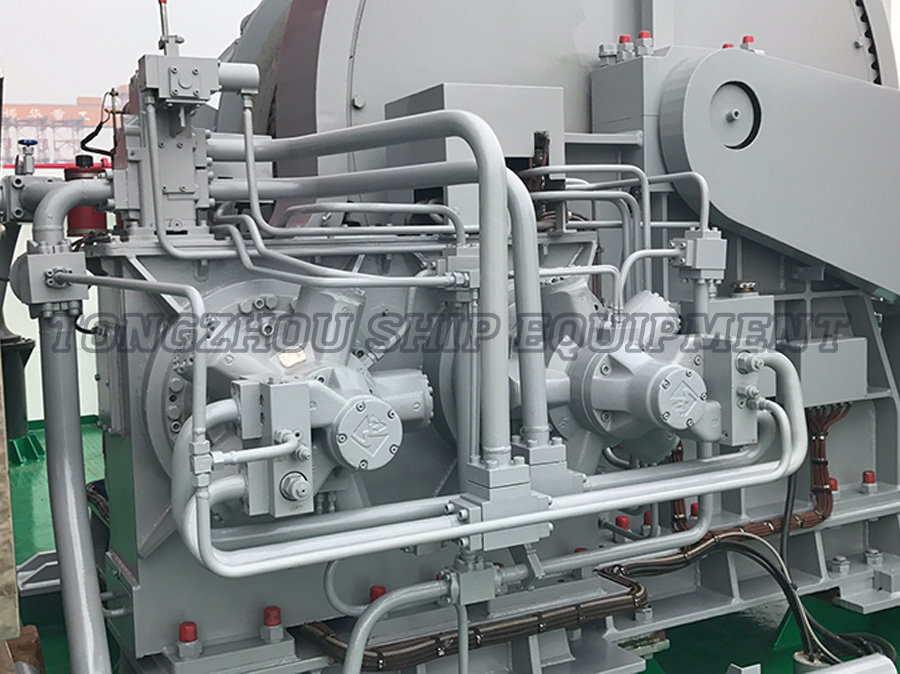

Hydraulic Motor: Mounted directly on or near the windlass frame, this component is the primary actuator. Pressurized hydraulic oil from the HPU enters the motor, forcing internal components (gears, pistons, or vanes) to rotate. This rotation generates torque.

-

Efficiency Factor: The motor's volumetric efficiency (minimizing internal leakage) and mechanical efficiency (minimizing friction losses) directly impact overall system efficiency. High-quality motors designed for high torque at low speeds are essential.

-

-

Gear Reduction Unit: The rotational speed output from the hydraulic motor is typically too high and the torque too low for direct anchor handling. A robust, multi-stage gearbox (usually integral to the windlass) significantly reduces the output speed while multiplying the torque delivered to the chainwheel shaft. Gear design and precision manufacturing minimize friction losses within this critical component.

-

Chainwheel/Gypsy Head & Brake: The high-torque, low-speed output from the gearbox drives the chainwheel. Its precisely machined pockets engage the links of the anchor chain. A powerful band brake, often hydraulically or manually applied, securely holds the chain when the windlass is not powered, especially under load.

Achieving and Maintaining Operational Efficiency

The inherent design of a Hydraulic Windlass offers pathways to efficiency, but realizing it consistently requires attention to several factors:

-

Proper System Sizing and Matching: Efficiency starts at the design stage.

-

The HPU capacity (pump flow and pressure rating) must be correctly matched to the torque and speed requirements of the hydraulic motor and the load profile of the windlass (chain size, expected pull, water depth).

-

The hydraulic motor must be sized to deliver sufficient torque at the required chainwheel speed without excessive pressure drop or heat generation.

-

Undersized components will be overloaded and inefficient; oversized components lead to unnecessary energy consumption and heat buildup.

-

-

Optimized Hydraulic Circuit Design:

-

Accumulators: Strategically placed hydraulic accumulators can store pressurized fluid. During peak demand (e.g., initial chain breakout), the accumulator supplements pump flow, allowing for a smaller, more efficient pump to handle average loads. This smoothens operation and reduces pump cycling.

-

Efficient Control Valves: Valves with low pressure drop characteristics minimize energy loss during fluid direction changes. Proportional valves can offer finer control and potentially better efficiency than simple on/off types.

-

Adequate Line Sizing: Hydraulic lines (hoses or pipes) must be correctly sized. Undersized lines create high flow resistance (pressure drop), leading to energy loss as heat and reduced performance at the motor. Oversized lines add unnecessary weight and cost.

-

-

High-Quality Components and Precision Manufacturing: Efficient power transmission relies on minimizing internal losses:

-

Motor and Pump Efficiency: Selecting components with high volumetric and mechanical efficiency ratings ensures more hydraulic energy is converted to useful mechanical work.

-

Gearbox Efficiency: Precision-cut gears with appropriate lubrication minimize friction losses within the reduction unit.

-

Seals and Bearings: High-quality seals minimize internal leakage, while properly lubricated and sized bearings reduce friction.

-

-

Optimal Fluid Selection and Maintenance: Hydraulic fluid is the lifeblood of the system.

-

Correct Viscosity: Using fluid with the viscosity grade specified by the windlass and HPU manufacturers is crucial. Fluid that's too thick increases resistance and power loss; fluid that's too thin increases internal leakage.

-

Fluid Cleanliness: Contamination (water, air, particles) is the primary cause of hydraulic component wear and failure. Rigorous filtration (both in the reservoir and via in-line filters) and regular fluid analysis are paramount for maintaining efficiency and longevity. Degraded or contaminated fluid increases friction, wear, and internal leakage.

-

Fluid Condition: Maintaining proper fluid level and preventing overheating (through adequate reservoir sizing and cooling if necessary) preserves fluid properties and prevents oxidation and viscosity breakdown.

-

-

Proper Operation and Maintenance:

-

Avoid Overloading: Consistently exceeding the windlass's rated working load promotes inefficiency through excessive slippage, heat generation, and accelerated wear.

-

Regular Inspection and Lubrication: Following the manufacturer's maintenance schedule for inspecting gears, bearings, brakes, seals, and lubricating points prevents minor issues from escalating into major efficiency losses or failures.

-

System Checks: Monitoring for leaks, unusual noises, excessive heat, or slow operation allows for early intervention before efficiency degrades significantly.

-

A Hydraulic Windlass achieves efficiency through a combination of robust engineering principles and diligent operational practices. Its core strength lies in delivering high torque reliably at low speeds, essential for anchor handling. Realizing sustained efficiency requires precise component matching, optimized hydraulic circuit design, the use of high-quality parts, meticulous attention to hydraulic fluid cleanliness and condition, and adherence to proper operating and maintenance procedures. By understanding these interconnected factors, vessel operators can ensure their Hydraulic Windlass performs its critical role effectively and economically throughout its service life.

English

English  عربى

عربى  中文简体

中文简体