What Are Common Troubleshooting Steps for a Marine Hydraulic Anchor Windlass Failure?

2025.07.06

2025.07.06

Industry News

Industry News

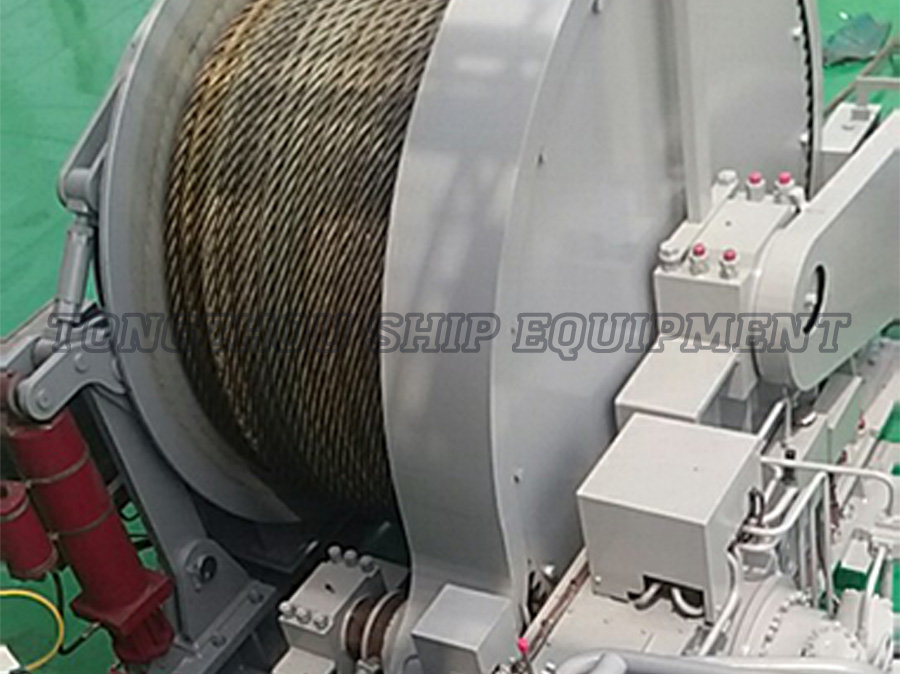

A hydraulic anchor windlass is a critical piece of equipment for vessel safety and operations. When it fails, it can strand a vessel, compromise safety, and lead to costly delays. Addressing failures quickly and correctly is paramount. Here’s a structured, professional guide to common troubleshooting steps:

1. Initial Safety and System Isolation: * Secure Power: Immediately shut down the hydraulic power unit (HPU) – turn off the pump motor and ensure controls are in neutral. * Relieve Pressure: Carefully operate the control levers (if possible) to release residual pressure in the hydraulic lines. Use pressure gauges if equipped. * Engage Brakes/Clutches: Ensure the windlass brake or clutch is firmly engaged to prevent any unexpected movement of the chain or rope.

2. Visual Inspection & Basic Checks: * Hydraulic Fluid Level: Check the reservoir sight glass or dipstick. Low fluid is a common cause of system cavitation, overheating, and loss of power. Top up only with the recommended fluid type after identifying potential leaks. * Fluid Condition: Inspect the fluid. Milky appearance indicates water contamination. Dark, opaque, or burnt-smelling fluid suggests overheating or degradation. Gritty feel or visible particles signal contamination. Severely degraded fluid requires a full system flush. * Leaks: Perform a thorough visual inspection of the entire system: * Hydraulic reservoir, pump, valves, and motor seals. * All hydraulic hose connections, fittings, and unions. * The hydraulic cylinder on deck (if applicable). * The windlass motor itself. * Mechanical Binding: Manually attempt to rotate the gypsy or wildcat (with the brake/clutch disengaged only if safe). Check for seized bearings, debris jamming the chainwheel, or damaged gears. Inspect the anchor chain/rope for kinks, shackles catching, or improper lead.

3. Operational Diagnosis & Component Testing: * Listen for Sounds: When restarting the HPU (briefly, under low load/no load after checks), listen for unusual noises: * Loud whining or cavitation noise suggests pump starvation (low fluid, clogged suction filter, air ingress). * Grinding or knocking sounds indicate potential pump, motor, or mechanical bearing failure. * High-pitched squealing might point to relief valve operation or severe cavitation. * Check Pressure Readings (Crucial): * If pressure gauges are installed at the pump outlet and/or windlass motor inlet, note readings when operating controls in both directions under load (if possible safely) and against the brake. Compare to normal operating pressures documented in the manual. * Low Pressure: Often indicates pump wear, internal leakage in valves or the motor, relief valve stuck open, or significant external leaks. * No Pressure: Points to pump failure, major leak, seized pump drive, or severely clogged filter/suction line. * Excessively High Pressure: Can signal a blocked line, malfunctioning pressure control valve, or internal binding/seizure downstream. * Control Valve Function: Ensure control levers/cables are properly connected and moving the valve spool fully. Listen/feel for the distinct "click" as the spool shifts. Sticky or slow operation can indicate internal valve contamination or wear. * Heat Check: Carefully feel hydraulic lines and components after shutdown. Excessive heat in a specific area can indicate a restriction or internal leakage point.

4. Addressing Specific Symptoms:

- Windlass Runs Slow/Weak:

- Primary suspects: Low fluid, fluid contamination/degradation, pump wear, internal motor leakage, restricted flow (clogged filter), air in system, low system pressure.

- Windlass Doesn't Run At All (Motor Silent):

- Check: Electrical power to HPU motor, fuses, motor starter. HPU motor failure. Severely seized mechanical components jamming the motor.

- Windlass Doesn't Run (Motor Runs):

- Check: Pump drive coupling failure. Pump catastrophic failure. Complete blockage in suction line or catastrophic leak preventing pressure build-up. Severe internal valve blockage.

- Windlass Operates in One Direction Only:

- Focus on: Directional control valve spool for the affected direction (stuck, damaged seals). Blocked pilot line on solenoid valves (if applicable). Faulty limit switch or electrical control for one direction.

- Windlass Drifts/Lowers Under Load:

- Likely causes: Failed or leaking hydraulic motor internal seals. Malfunctioning or incorrectly set counterbalance valve. Leaking control valve spool seals. External leaks past the motor shaft seal.

5. Systematic Verification & Next Steps:

- Document Findings: Record all observations, pressures, symptoms, and steps taken.

- Prioritize Simple Fixes: Address obvious leaks, top up/replace fluid, clean/replace filters if contamination is mild.

- Component Isolation: If possible and safe, isolate sections (e.g., bypass the control valve temporarily using test hoses per manual procedures) to pinpoint the faulty component.

- Consult Manuals: Refer to the specific windlass and hydraulic system technical manuals for schematics, pressure specifications, and troubleshooting charts.

- Professional Assistance: If the fault isn't readily identifiable through basic checks or requires component disassembly (pump, motor, valve rebuild), or involves complex hydraulic diagnosis, engage qualified marine hydraulic technicians. Improper disassembly or adjustment can cause further damage or safety hazards.

Hydraulic windlass failures demand a methodical approach. Starting with safety and fundamental checks (fluid, leaks, binding) before progressing to operational diagnosis and pressure readings provides the best path to identifying the root cause. While some issues like low fluid or clogged filters can be rectified onboard, many hydraulic failures require specialized knowledge and tools. Consistent maintenance, including fluid analysis and periodic system inspections, is the most effective strategy for preventing costly and dangerous windlass failures at critical moments.

English

English  عربى

عربى  中文简体

中文简体