Why is Regular Maintenance Crucial for Your Marine Hydraulic Anchor Windlass?

2025.06.19

2025.06.19

Industry News

Industry News

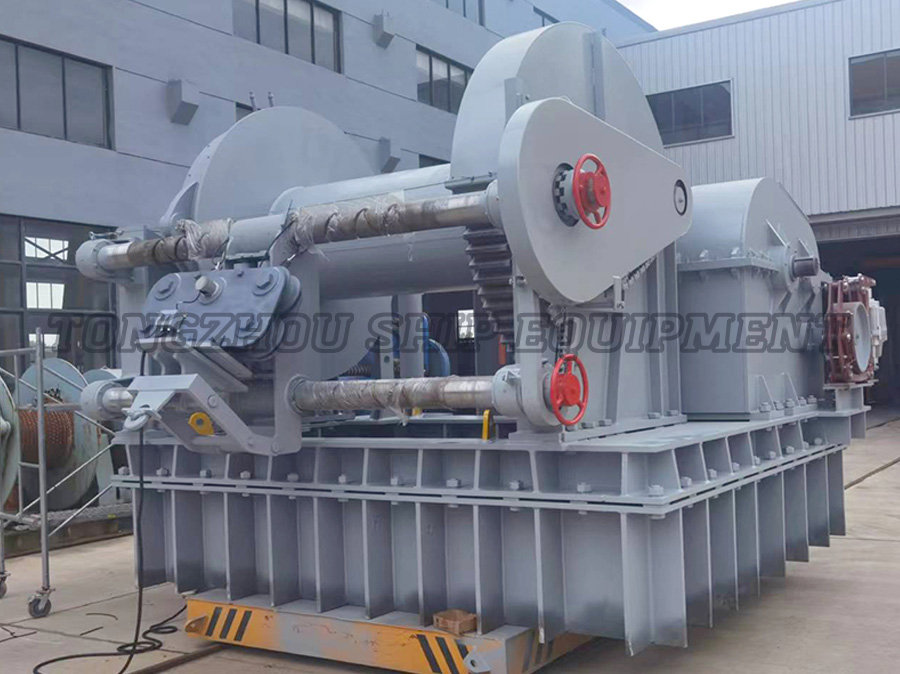

In the unpredictable world of maritime operations, the reliability of essential equipment can mean the difference between a smooth voyage and a life-threatening crisis. Among these critical components, the marine hydraulic anchor windlass—a device that handles the heavy lifting of anchors and chains through hydraulic power—often goes unnoticed until it fails. Yet, neglecting its upkeep can lead to catastrophic consequences, from vessel strandings to costly repairs.

Hydraulic anchor windlasses are designed to withstand the harsh marine environment, but their complex mechanisms are vulnerable to wear and tear. Without routine upkeep, common issues like hydraulic fluid contamination, seal degradation, or corrosion can escalate quickly. For instance, seawater exposure accelerates rust in metal parts, while particulate buildup in hydraulic lines reduces efficiency and increases stress on the system. Such failures can impair the windlass's ability to deploy or retrieve anchors reliably, especially during emergencies like sudden storms. This risks vessel drift, collisions, or even personnel injuries—scenarios that maritime authorities globally cite as preventable with proper maintenance protocols.

The benefits of adhering to a structured maintenance schedule are multifaceted. First and foremost, it enhances safety by ensuring the windlass responds instantly when needed, critical for avoiding groundings or aiding in rescue operations. Secondly, it boosts cost-efficiency; preventative measures like annual fluid changes and component inspections are far less expensive than emergency repairs or full replacements, which can run into thousands of dollars. Regular checks also prolong the equipment's lifespan, maintaining optimal performance and reducing downtime. Industry guidelines, such as those from classification societies, often mandate such routines to comply with safety standards, underscoring their non-negotiable role in operational compliance.

To safeguard your windlass, implement a proactive maintenance plan. Start with visual inspections every few months, checking for leaks, unusual noises, or visible corrosion. Schedule professional servicing at least annually to test hydraulic pressure, replace filters, and lubricate moving parts. Always use manufacturer-approved fluids and components to avoid compatibility issues. By integrating these steps into your vessel's routine, you not only protect your investment but also contribute to a safer maritime ecosystem.

In essence, regular maintenance transforms the hydraulic anchor windlass from a potential liability into a dependable asset. Ignoring it invites unnecessary risks and expenses, while embracing it ensures seamless voyages and peace of mind. For vessel operators, prioritizing this discipline is a straightforward step toward safeguarding lives, assets, and the sea itself.

English

English  عربى

عربى  中文简体

中文简体