Why is the Electric Windlass Widely Used in Maritime Applications?

2025.10.31

2025.10.31

Industry News

Industry News

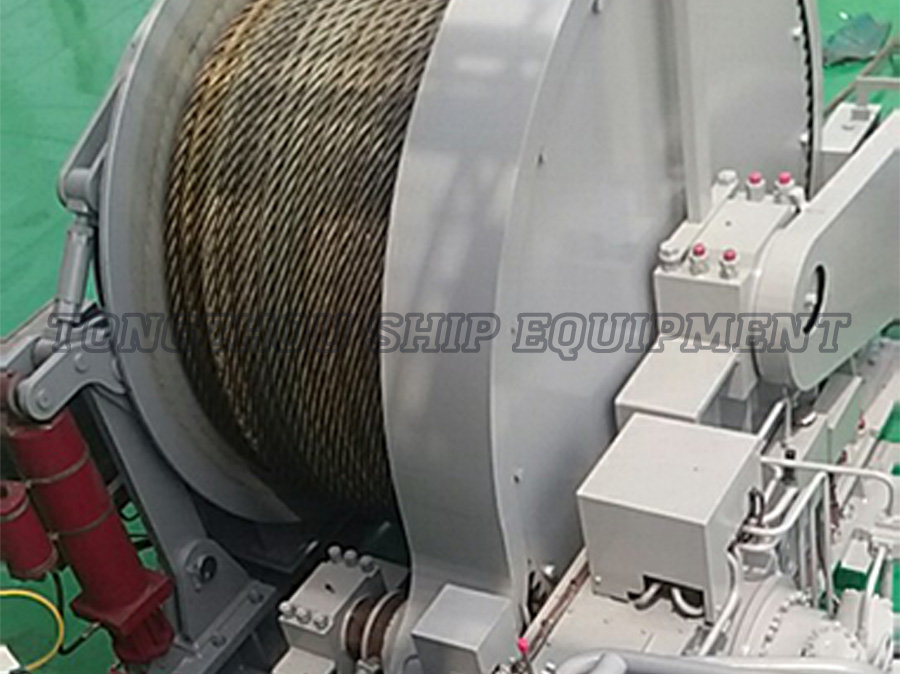

The electric windlass is a crucial piece of equipment in modern maritime operations, known for its efficiency and reliability in anchoring and mooring vessels. As an electrically powered mechanical device, the electric windlass has become indispensable in both recreational and commercial shipping industries.

The Functionality and Importance of Electric Windlasses

An electric windlass is primarily used to raise and lower the anchor on a boat or ship. It combines the convenience of electric power with the mechanical efficiency required for handling heavy chains and anchors. This is particularly important in situations where manual labor would be insufficient or too demanding.

Ease of Operation

One of the most significant advantages of an electric windlass is its ease of operation. With just a push of a button or flip of a switch, sailors can effortlessly raise or lower the anchor without needing extensive manual effort. This ease of use significantly reduces fatigue, especially during repeated anchor drops in challenging weather conditions.

Increased Efficiency and Speed

Electric windlasses are designed to perform faster than manual counterparts, allowing the crew to operate the anchor system more efficiently. This quick operation is vital in commercial shipping, where time is critical, and any delays in the anchoring process can result in additional fuel consumption or missed deadlines.

Why Choose Electric Windlass Over Manual Systems?

While manual windlasses have been traditionally used in maritime applications, electric windlasses offer a number of advantages that make them the preferred choice for modern vessels.

Reduced Labor Costs

Manual windlasses require significant physical effort from the crew, especially when handling larger ships or multiple anchors. Electric windlasses eliminate much of this physical labor, reducing the need for manual crew intervention. This not only leads to improved crew safety but also reduces the overall labor costs associated with anchoring operations.

Enhanced Safety

Operating an anchor manually involves several safety risks, particularly when the anchor is heavy or in rough sea conditions. With an electric windlass, the crew is at a safe distance from the anchor, which mitigates the risk of injury. The automatic nature of the electric windlass also ensures that anchors are deployed in a controlled manner, reducing the risk of damage to the vessel or surrounding environment.

Durability and Reliability in Harsh Conditions

Electric windlasses are designed to withstand the harsh marine environment, where constant exposure to saltwater and wind can cause wear and tear on mechanical systems. High-quality electric windlasses are built to endure such conditions, ensuring long-term durability and reliability.

Corrosion-Resistant Materials

To combat the corrosive effects of saltwater, electric windlasses are typically constructed from high-grade stainless steel or other corrosion-resistant materials. This ensures that the windlass will continue to function effectively, even in challenging maritime climates.

Low Maintenance Requirements

Electric windlasses are also low-maintenance, requiring fewer repairs and servicing compared to manual or hydraulic models. This can lead to lower operational costs over the lifespan of the vessel. Regular maintenance checks ensure that the system continues to perform optimally, avoiding unexpected failures during critical moments.

Versatility for Various Maritime Operations

Electric windlasses are versatile and can be used across a wide range of vessels, from luxury yachts to large commercial ships. This versatility is crucial in ensuring that the windlass can meet the varying needs of different types of operations, whether it be for leisure cruising, offshore oil drilling, or cargo shipping.

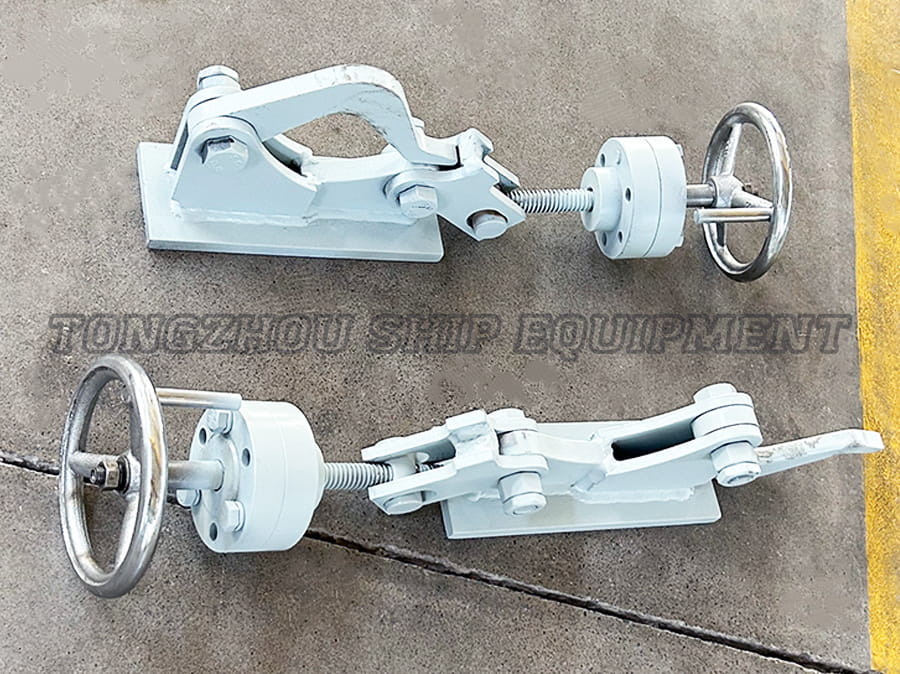

Compatibility with Different Anchors

Electric windlasses are designed to handle different sizes and types of anchors, making them adaptable for various maritime needs. Whether it is a lightweight anchor for a smaller boat or a heavy-duty model for a large vessel, the electric windlass can accommodate these demands with ease.

Integration with Other Systems

Modern electric windlasses can also be integrated with other onboard systems, such as GPS or automated mooring systems. This integration enhances the overall efficiency of the vessel’s operations and ensures seamless transitions from anchoring to navigation.

Conclusion

The electric windlass is an essential tool in modern maritime operations, offering significant advantages over manual systems in terms of efficiency, safety, and ease of use. Its ability to operate under harsh conditions, combined with reduced labor costs and enhanced reliability, makes it a preferred choice for vessels worldwide. As maritime technology continues to evolve, the electric windlass will remain a fundamental component for ensuring the smooth operation of both recreational and commercial vessels.

English

English  عربى

عربى  中文简体

中文简体