Why Should You Invest in an Electric Windlass for Your Commercial Vessel?

2025.12.05

2025.12.05

Industry News

Industry News

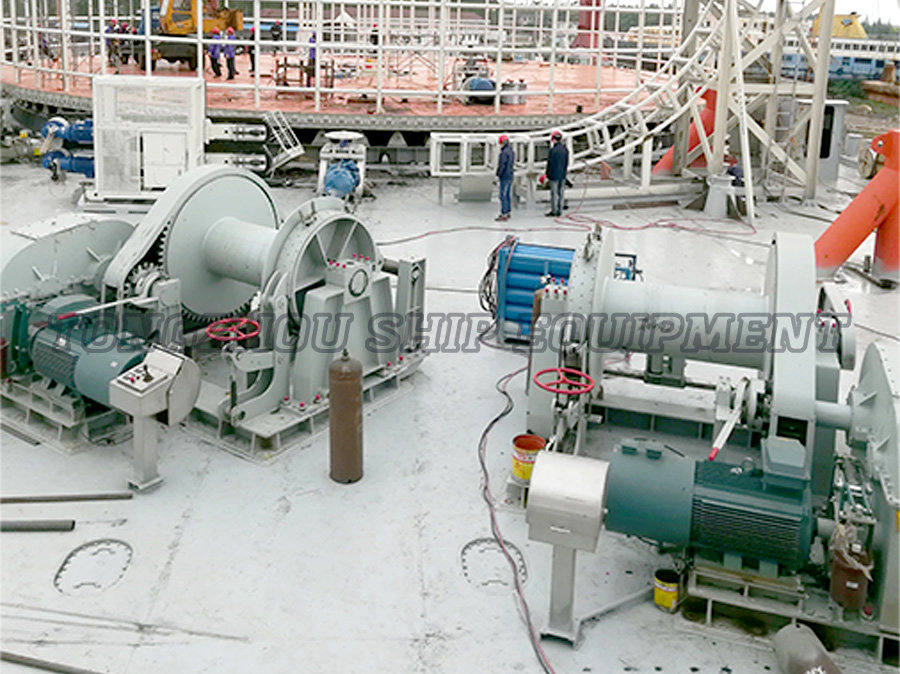

As global maritime trade continues to expand and port operations become increasingly automated, commercial vessel owners are under growing pressure to improve efficiency, safety, and operational reliability. One critical piece of deck machinery that plays a decisive role in daily operations is the Electric Windlass. From anchor handling to crew safety and operational speed, electric windlasses are rapidly becoming the industry standard across cargo ships, offshore vessels, fishing boats, and passenger ferries.

With rising fuel costs, stricter safety regulations, and the demand for smarter ship systems, investing in an Electric Windlass is no longer just a technical upgrade—it is a strategic business decision.

- Understanding What an Electric Windlass Is

- The Growing Importance of Electric Windlasses in Modern Shipping

- Key Advantages of an Electric Windlass for Commercial Vessels

- Applications Across Commercial Vessel Types

- Electric Windlass vs. Hydraulic and Manual Systems

- Technological Innovations in Electric Windlass Systems

- Cost Considerations and Return on Investment

- Installation and Compatibility with Modern Vessels

- Global Market Trends for Electric Windlass Equipment

- Compliance with International Maritime Safety Standards

- How Electric Windlasses Improve Crew Working Conditions

- Maintenance Best Practices for Long-Term Performance

- Future Development of Electric Windlass Technology

- Frequently Asked Questions (FAQ)

- What size Electric Windlass is suitable for a commercial vessel?

- Is an Electric Windlass reliable for heavy-duty offshore operations?

- How long does an Electric Windlass typically last?

- Can Electric Windlasses operate in extreme weather?

- Is it possible to upgrade from hydraulic to electric systems?

- Do Electric Windlasses require special crew training?

- Key Considerations When Choosing an Electric Windlass Supplier

- Conclusion: A Strategic Investment for Long-Term Maritime Success

Understanding What an Electric Windlass Is

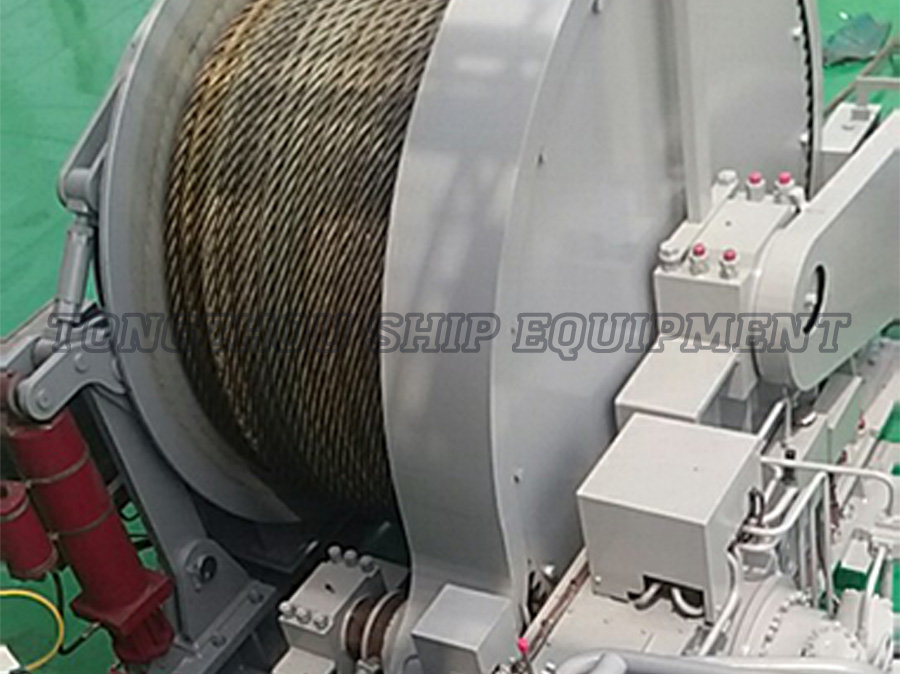

Definition and Core Function

An Electric Windlass is a powered deck machine designed to raise, lower, and control a vessel’s anchor using electric motor-driven mechanisms. Unlike manual or hydraulic systems, electric windlasses operate entirely through electrical power, offering consistent torque, precise control, and smoother operation.

Main Components of an Electric Windlass

- Electric Motor: Supplies driving power.

- Gearbox: Transfers torque to the gypsy or drum.

- Gypsy Wheel: Engages with the anchor chain.

- Drum: Handles rope or cable when applicable.

- Brake System: Controls anchor descent and holds load.

- Control Panel: Allows remote or local operation.

These components work together to deliver stable, controlled anchoring performance under demanding maritime conditions.

The Growing Importance of Electric Windlasses in Modern Shipping

Commercial vessels are becoming more technologically advanced, integrating electric propulsion systems, smart sensors, and automated deck machinery. Within this ecosystem, the Electric Windlass aligns perfectly with modern ship design philosophies that prioritize efficiency, digital control, and reduced maintenance.

Ports now demand faster turnaround times. Crews expect safer working conditions. Fleet operators seek consistent performance across different vessel classes. These trends explain the steady shift from manual and hydraulic systems to electric windlasses worldwide.

Key Advantages of an Electric Windlass for Commercial Vessels

1. Operational Efficiency and Speed

An Electric Windlass delivers rapid anchor deployment and retrieval with minimal lag. This allows vessels to:

- Reduce docking and departure times

- Minimize delays at busy ports

- Improve fleet scheduling reliability

2. Enhanced Safety Standards

Manual anchoring systems expose crew members to risks such as sudden chain release, physical strain, and mechanical failure. Electric windlasses improve safety by:

- Preventing uncontrolled anchor drops

- Reducing human fatigue and injury

- Enabling emergency stop mechanisms

3. Precision Control in Harsh Conditions

Weather conditions at sea can change rapidly. Electric control systems allow for accurate chain tension adjustment, ensuring stable anchoring even during strong currents, wind, or rough seas.

4. Lower Maintenance Requirements

Compared with hydraulic windlasses, which rely on oil systems and complex piping, electric windlasses have fewer mechanical wear points. This results in:

- Reduced oil leaks

- Simplified maintenance routines

- Lower downtime and repair costs

5. Energy Efficiency and Environmental Compliance

Modern Electric Windlass models are built with high-efficiency motors that optimize power usage. With stricter environmental regulations governing marine equipment, electric solutions help vessels meet sustainable operation goals.

Applications Across Commercial Vessel Types

Cargo and Container Ships

Large cargo vessels require powerful anchoring systems capable of handling heavy chains and deep-water conditions. Electric windlasses provide the torque strength and reliability needed for large-scale port operations.

Offshore Support Vessels

Dynamic positioning systems pair effectively with electric windlasses for anchoring stability near offshore platforms.

Fishing Vessels

Commercial fishing boats benefit from fast anchoring cycles that improve efficiency during shifting fishing zones.

Passenger Ferries and Cruise Ships

Quiet operation, smooth chain control, and crew safety make electric windlasses ideal for passenger-oriented vessels.

Electric Windlass vs. Hydraulic and Manual Systems

| Feature | Electric Windlass | Hydraulic Windlass | Manual Windlass |

|---|---|---|---|

| Power Source | Electric Motor | Hydraulic Pump | Human Force |

| Maintenance | Low | Moderate to High | Low |

| Operational Speed | Fast | Fast | Slow |

| Safety Level | High | High | Low |

| Environmental Impact | Low | Oil Leak Risk | Minimal |

The table clearly shows why the Electric Windlass stands out as the most balanced solution for modern commercial operations.

Technological Innovations in Electric Windlass Systems

Smart Control Integration

Advanced electric windlasses now feature PLC-based control, remote monitoring, and digital diagnostics for real-time fault detection.

Overload Protection Systems

Automatic torque limiters protect both the anchor chain and gearbox from mechanical overload.

Variable Speed Drives (VFD)

VFD technology allows smooth acceleration and deceleration, minimizing impact stress during anchor deployment.

Cost Considerations and Return on Investment

While the upfront cost of an Electric Windlass may be higher than manual systems, the long-term financial benefits often outweigh the initial investment.

Key Cost Benefits

- Lower maintenance and oil replacement costs

- Reduced labor requirements

- Fewer operational delays

- Longer equipment service life

Fleet operators consistently report reduced life-cycle costs when using electric windlasses across multiple vessels.

Installation and Compatibility with Modern Vessels

Electric windlasses are designed to integrate seamlessly into new vessels and retrofit projects. Their compact structure allows flexible mounting options on foredeck, center deck, or customized layouts.

Voltage options typically range from 220V to 440V AC, making them compatible with global ship power standards.

Global Market Trends for Electric Windlass Equipment

The global demand for electric windlasses continues to grow alongside:

- Expansion of offshore energy projects

- Development of smart ports

- Stricter international safety regulations

- Growth in coastal passenger transport

Shipowners increasingly prioritize electric deck machinery when ordering newbuild vessels, ensuring stronger long-term resale value.

Compliance with International Maritime Safety Standards

Modern Electric Windlass systems comply with major certification standards, including:

- IMO (International Maritime Organization)

- ABS, DNV, BV, CCS Classification Societies

- CE and ISO Mechanical Safety Standards

This ensures legal compliance across international waters and simplifies inspection procedures.

How Electric Windlasses Improve Crew Working Conditions

Fatigue reduction, noise minimization, and simplified operation significantly improve onboard working conditions. Electric windlasses require fewer crew members at the foredeck and reduce physical strain during anchoring tasks.

Improved ergonomics also reduce accident rates and insurance risks for vessel operators.

Maintenance Best Practices for Long-Term Performance

Routine Inspection

- Check brake linings monthly

- Inspect electrical wiring for corrosion

- Monitor gearbox lubrication

Preventive Servicing

Scheduled preventive maintenance ensures stable performance under heavy load cycles and prolongs mechanical lifespan.

Future Development of Electric Windlass Technology

Future electric windlasses are expected to integrate artificial intelligence algorithms for load prediction, chain wear monitoring, and remote fleet-level condition tracking. These advancements will further enhance operational safety and reduce downtime.

Frequently Asked Questions (FAQ)

What size Electric Windlass is suitable for a commercial vessel?

The correct size depends on anchor weight, chain diameter, vessel displacement, and operational environment. Professional load calculation is required.

Is an Electric Windlass reliable for heavy-duty offshore operations?

Yes. High-capacity electric windlasses are engineered specifically for offshore support vessels and deep-water anchoring.

How long does an Electric Windlass typically last?

With proper maintenance, service life often exceeds 10–15 years.

Can Electric Windlasses operate in extreme weather?

Marine-grade motors and sealed gearboxes allow reliable operation in saltwater, high humidity, and temperature extremes.

Is it possible to upgrade from hydraulic to electric systems?

Yes. Many vessels successfully retrofit hydraulic windlasses with electric units, reducing oil system dependency.

Do Electric Windlasses require special crew training?

Basic operational training is sufficient due to the intuitive control systems used in modern designs.

Key Considerations When Choosing an Electric Windlass Supplier

- Manufacturing standards and certifications

- After-sales support and spare parts availability

- Customization capability

- Global service network

Reliable suppliers ensure consistent performance throughout the vessel’s operational life.

Conclusion: A Strategic Investment for Long-Term Maritime Success

Investing in an Electric Windlass is not merely a hardware upgrade—it is a strategic decision that enhances safety, efficiency, environmental compliance, and operational reliability. As the commercial maritime industry continues its shift toward automation and electrification, electric windlasses stand at the core of modern deck machinery innovation.

From reduced maintenance costs and improved crew safety to future-ready smart control integration, the electric windlass delivers measurable benefits across every stage of vessel operation. For shipowners focused on competitiveness, regulatory compliance, and long-term asset value, the decision to adopt electric windlass systems represents a forward-looking investment in maritime performance.

English

English  عربى

عربى  中文简体

中文简体