Can Hydraulic Windlass handle heavy anchors in rough seas?

2025.07.24

2025.07.24

Industry News

Industry News

The ability of hydraulic windlasses to manage heavy anchors in challenging sea conditions is a critical consideration for maritime operations. This guide examines the key aspects of hydraulic windlass performance, addressing factors like mechanical design, environmental resilience, and operational safety to provide a balanced, evidence-based perspective. As vessels increasingly navigate unpredictable waters, understanding the capabilities and limitations of hydraulic systems is essential for efficient and secure anchoring.

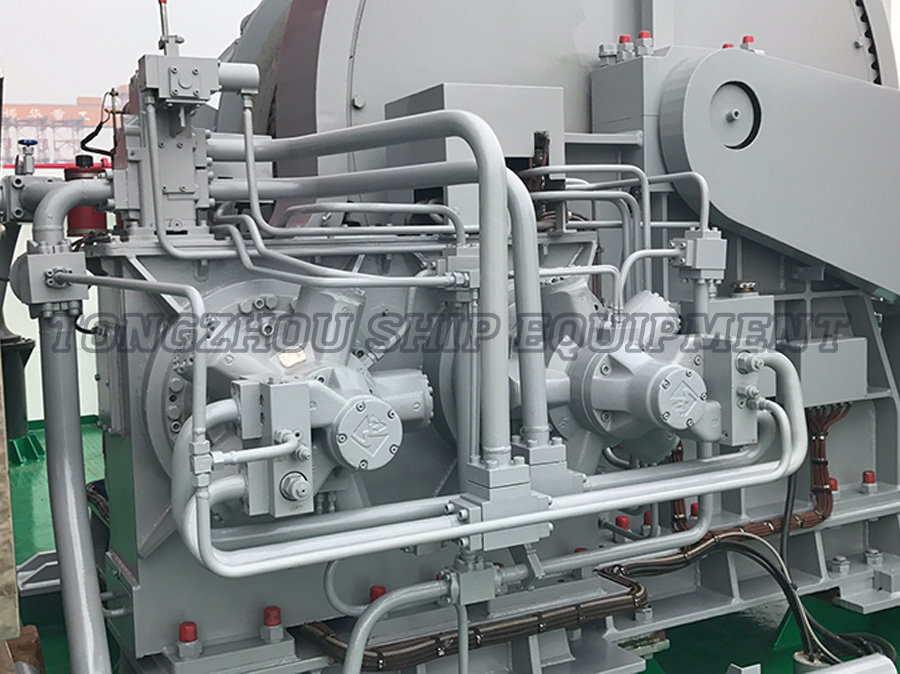

Hydraulic windlasses operate through a hydraulic motor driven by pressurized fluid, typically oil, which converts engine power into high-torque rotational force. This mechanism enables the controlled raising or lowering of anchor chains and anchors. The system's design often incorporates robust components, such as hardened steel gears and corrosion-resistant materials, to withstand marine environments. For heavy anchors—defined as those exceeding standard weights, often above 500 kg for smaller vessels—hydraulic windlasses are engineered to deliver consistent pulling power. This is achieved through calibrated pressure systems that maintain force even under load fluctuations, reducing the risk of slippage or failure.

In rough seas, characterized by high waves, strong winds, and vessel pitching, anchoring operations face amplified challenges. Hydraulic windlasses demonstrate resilience due to several inherent advantages. First, hydraulic systems provide smooth, controlled motion, minimizing jerking motions that could compromise stability on a moving deck. Second, they offer scalability; higher-pressure setups can handle anchors weighing several tons by distributing load evenly across the winch drum and chain stopper. However, performance depends on installation quality—poorly mounted systems may experience leaks or pressure drops in turbulent conditions. For instance, hydraulic fluid viscosity remains stable across temperature variations, ensuring reliable operation in cold or stormy scenarios, but seal integrity must be maintained to prevent contamination from seawater ingress.

Handling heavy anchors requires attention to power output and safety protocols. Hydraulic windlasses typically generate torque proportional to system pressure, with common models rated for loads up to 10,000 kg or more, depending on vessel size. This capacity allows for efficient retrieval of large anchors, even in adverse weather. To ensure effectiveness, operators should adhere to manufacturer guidelines for load limits and conduct pre-operation checks, such as verifying hydraulic fluid levels and inspecting for wear on chains and gypsies. In rough seas, best practices include deploying anchors gradually to absorb shock loads and using secondary holding devices to augment security. Regular maintenance—such as fluid changes and component inspections every 500 operating hours—enhances longevity and prevents malfunctions that could exacerbate risks in high-stress situations.

Ultimately, hydraulic windlasses are well-suited for managing heavy anchors in rough seas when properly maintained and operated. Marine industry standards support their use in diverse conditions, citing reliability from reduced mechanical wear compared to electric alternatives. By prioritizing routine upkeep and situational awareness, vessel operators can leverage hydraulic systems for dependable anchoring, underscoring their role in safe maritime navigation.

English

English  عربى

عربى  中文简体

中文简体