How to optimize Hydraulic Windlass performance for efficiency?

2025.08.03

2025.08.03

Industry News

Industry News

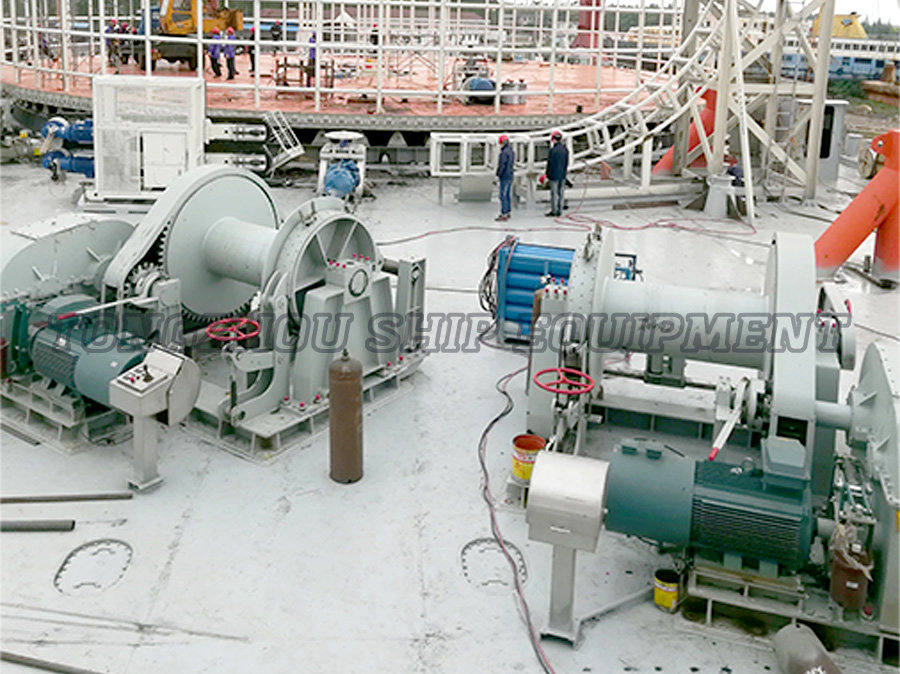

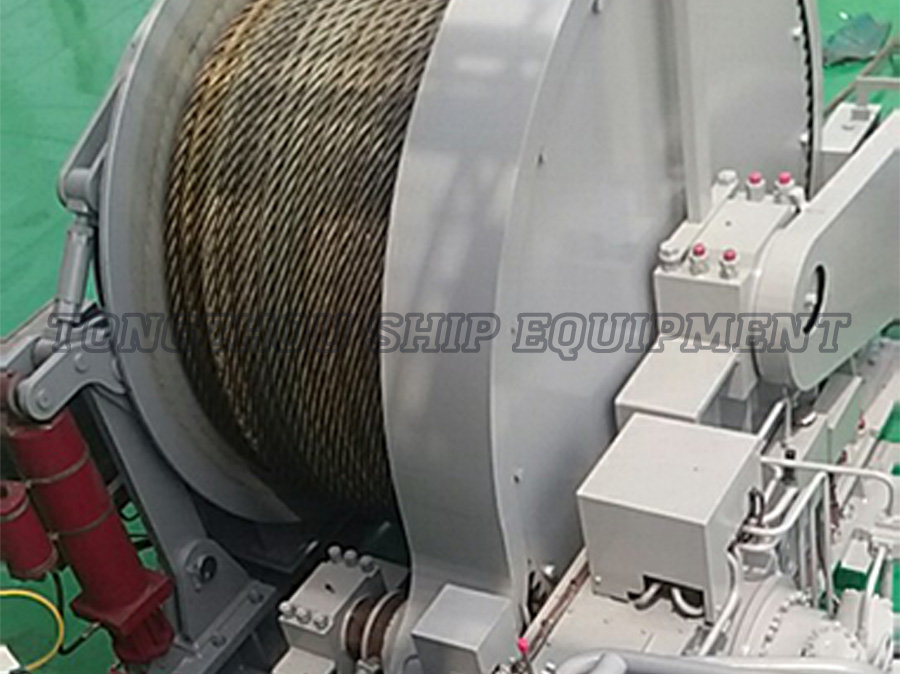

The hydraulic windlass is a critical component for safe and efficient vessel anchoring operations. Maximizing its performance isn't just about raw power; it's about ensuring smooth, reliable, and energy-efficient operation. Proper maintenance and operational practices directly impact efficiency, reducing wear, minimizing downtime, and extending the lifespan of this vital equipment.

-

Maintain Optimal Hydraulic Fluid Condition:

-

Viscosity & Quality: Ensure the hydraulic fluid meets the manufacturer's specified viscosity grade (ISO VG) for the operating temperature range. Incorrect viscosity increases internal friction, reducing efficiency and potentially causing overheating. Regularly test fluid quality (e.g., through oil analysis) for viscosity breakdown, oxidation, and additive depletion.

-

Cleanliness: Contamination (water, air, particulates) is the primary enemy of hydraulic efficiency and component longevity. Maintain strict filtration using the correct micron-rated filters. Regularly check and replace filters according to schedule or differential pressure indicators. Ensure breather caps are clean and functioning. Keep the reservoir clean and check fluid levels routinely.

-

-

Ensure Correct System Pressure and Flow:

-

Calibration: The hydraulic windlass relies on specific pressure settings for optimal clutch, brake, and motor operation. Periodically verify and calibrate system pressure using accurate gauges against the manufacturer's specifications. Incorrect pressure can lead to slippage (inefficiency, wear) or excessive strain (inefficiency, potential damage).

-

Flow Rate: Confirm the hydraulic power unit (HPU) delivers the required flow rate. Insufficient flow slows operation and strains components; excessive flow wastes energy and generates unnecessary heat. Ensure pump condition is good and system restrictions (like kinked lines or undersized fittings) are absent.

-

-

Optimize Chain/Rope Handling and Alignment:

-

Fairlead Alignment: Precise alignment between the chain gypsy or rope warping head and the bow roller/fairlead is paramount. Misalignment causes excessive friction, accelerated wear on the chain/rope and gypsy/warping head, and forces the Hydraulic Windlass motor to work harder, consuming more energy. Regularly inspect and adjust alignment.

-

Gypsy/Rope Compatibility: Ensure the chain gypsy precisely matches the chain grade and size. Ensure the rope warping head is suitable for the rope diameter and type. Mismatches cause slippage, inefficient hauling, and rapid wear.

-

Lubrication: Apply appropriate marine-grade lubricant to the chain during retrieval to reduce friction over the bow roller and through the hawse pipe, lessening the load on the Hydraulic Windlass.

-

-

Implement Rigorous Inspection and Maintenance Schedules:

-

Visual & Functional Checks: Regularly inspect the Hydraulic Windlass for leaks (oil, hydraulic fluid), loose mounting bolts, corrosion, and wear on mechanical components (clutch discs, brake bands, bearings, gears).

-

Seal Integrity: Check shaft seals on the hydraulic motor and gearbox for leaks. Worn seals allow contamination ingress and fluid loss, impacting efficiency and reliability.

-

Tighten Connections: Vibration can loosen hydraulic fittings and electrical connections. Regularly check and torque to specifications. Loose hydraulic fittings cause leaks and pressure drops; loose electrical connections can cause motor inefficiency or failure.

-

Brake and Clutch Adjustment: Ensure brakes hold securely and disengage fully. Clutches must engage positively without slippage. Adjust according to the manufacturer's procedures as wear occurs.

-

-

Employ Efficient Operational Techniques:

-

Avoid Shock Loading: Engage the Hydraulic Windlass clutch smoothly. Avoid sudden jerks or dropping the anchor freely onto the brake, which creates massive shock loads inefficiently absorbed by the system and damaging components.

-

Use Appropriate Power: Use only the power necessary for the task. Avoid running the HPU at maximum pressure/flow unless absolutely required for breaking out a deeply set anchor. Moderate power settings are generally more efficient.

-

Monitor Load: Be attentive to the load on the windlass. Excessive strain indicates potential problems (fouled anchor, misalignment, mechanical issue) that reduce efficiency and risk damage.

-

-

Consider Environmental Factors:

-

Temperature: Hydraulic fluid viscosity changes with temperature. Ensure the fluid is suitable for the operating climate. Cold starts may require warm-up periods; hot climates demand fluid with high oxidation stability and adequate cooling.

-

Corrosion Protection: Saltwater exposure necessitates diligent cleaning, application of corrosion inhibitors on exposed metal parts (following manufacturer guidance), and use of appropriate materials in the hydraulic system.

-

The Efficiency Payoff:

By diligently implementing these practices, vessel operators can significantly optimize their Hydraulic Windlass performance. Benefits include:

-

Reduced Energy Consumption: Efficient operation lowers the load on the HPU, saving fuel or electrical power.

-

Extended Component Life: Minimized wear and correct operation prolong the lifespan of the motor, pump, valves, seals, gypsy, and brake components.

-

Enhanced Reliability: Consistent performance reduces the risk of failure during critical anchoring maneuvers.

-

Lower Operating Costs: Reduced energy use, fewer repairs, and longer intervals between major overhauls contribute to lower total cost of ownership.

-

Improved Safety: A well-maintained and efficiently operating Hydraulic Windlass is fundamental to safe anchoring and mooring operations.

Optimizing a Hydraulic Windlass is an ongoing process requiring attention to detail and adherence to maintenance protocols. Investing time and resources in these areas translates directly to more efficient, reliable, and cost-effective vessel operations. Always prioritize consulting the specific manufacturer's operation and maintenance manual for your equipment.

English

English  عربى

عربى  中文简体

中文简体