How Does a Marine Hydraulic Anchor Windlass Safely Handle Anchor Retrieval?

2025.06.01

2025.06.01

Industry News

Industry News

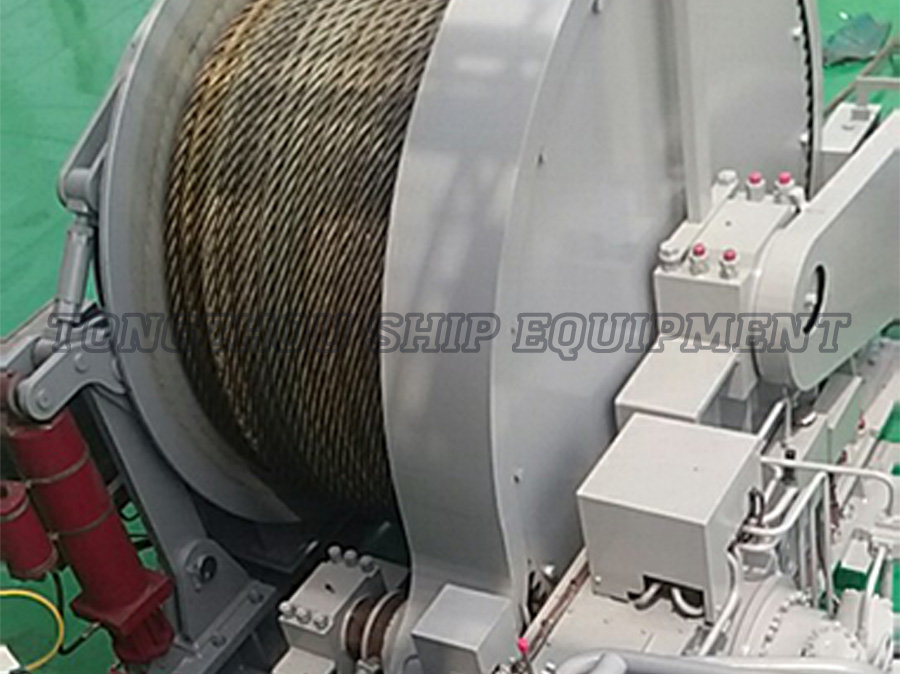

Securing a vessel safely at anchor is fundamental to maritime operations. Equally critical, yet often fraught with potential hazards, is the process of retrieving that anchor – a massive weight potentially buried deep in challenging seabeds. Here, the Marine Hydraulic Anchor Windlass stands as a vital piece of deck machinery, engineered specifically to manage the heavy loads and unpredictable forces involved in anchor recovery safely and efficiently.

The Core: Hydraulic Power Transmission

Unlike purely electric or mechanical windlasses, a Marine Hydraulic Anchor Windlass utilizes pressurized hydraulic fluid as its power medium. A central hydraulic power unit (HPU), typically located in a protected machinery space, generates this pressure. Fluid is pumped through robust hoses to the windlass motor mounted on deck.

This hydraulic drive offers inherent safety advantages:

Smooth Power Delivery: Hydraulic systems provide exceptional control over torque and speed. The operator can finely adjust the hauling force, allowing for gentle starts and stops, preventing shock loads on the chain and deck structure that could cause damage or failure.

High Torque at Low Speeds: Retrieving an anchor, especially when it's stuck or heavily embedded, requires immense pulling force. Hydraulic motors excel at delivering high torque even at very low rotational speeds, ideal for the slow, powerful hauling needed to break the anchor free.

Overload Protection: Hydraulic systems incorporate relief valves. If the load exceeds a safe limit (e.g., the anchor is deeply fouled), these valves open, diverting fluid and preventing pressure from building to dangerous levels that could rupture hoses or damage the motor. This protects both personnel and equipment.

Integrated Safety Mechanisms

Beyond the inherent properties of hydraulics, the Marine Hydraulic Anchor Windlass incorporates specific safety features:

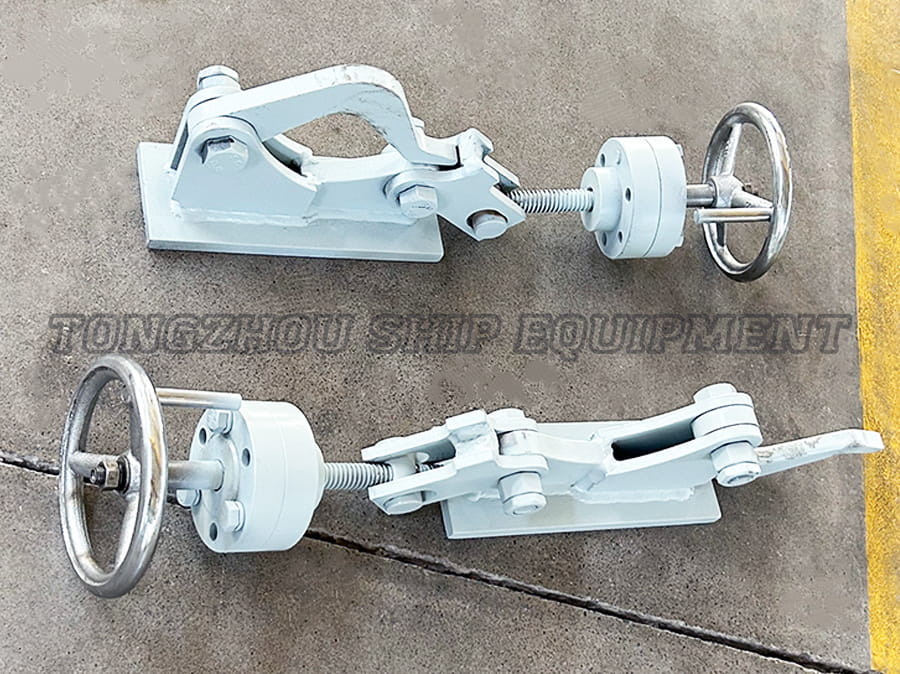

Robust Band Brake: The most critical safety component. This mechanically applied brake, often operated hydraulically or manually via a wheel, acts directly on the chain gypsy (wildcat). When engaged, it holds the anchor chain securely, preventing uncontrolled running out (dropping) of the anchor and chain under load. Its holding power is rated far beyond the windlass's hauling capacity.

Controlled Pay-Out: Retrieval isn't just about hauling in. Sometimes, controlled release of chain is needed to maneuver the vessel or free a snagged anchor. The hydraulic system allows for precise metering of chain speed during pay-out, preventing dangerous free-fall.

Secure Chain Holding: The design of the gypsy (wildcat) ensures the chain links are positively engaged during hauling, minimizing the risk of slippage or "jumping" under load.

Fail-Safe Considerations: Well-designed systems incorporate features like spring-applied, hydraulically released brakes. This means if hydraulic pressure is lost (e.g., engine failure), the brake automatically engages to hold the anchor chain securely.

Handling Real-World Retrieval Challenges

The true test of a Marine Hydraulic Anchor Windlass comes during difficult retrievals:

Breaking Out the Anchor: When suction or mud holds the anchor fast, the windlass must apply sustained, immense force. The hydraulic system's ability to deliver high torque steadily allows it to gradually work the anchor free without dangerous jerking or overload spikes.

Shock Loads from Swell: In heavy seas, the vessel's pitching can create sudden, severe tension spikes on the chain. The hydraulic system's inherent damping effect and smooth power transmission absorb much of this shock, protecting the machinery and deck fittings.

Fouled Anchors: If the anchor is caught on an obstruction, the operator can use controlled hauling and paying out ("snubbing") maneuvers. The precise control offered by the hydraulic windlass is essential for these delicate operations to free the anchor without risking damage or parting the chain.

Operational Safety Synergy

Crucially, the safety of anchor retrieval relies not just on the Marine Hydraulic Anchor Windlass itself, but on its integration with the vessel's systems and proper crew procedures. Adequate hydraulic power supply, regular maintenance (checking fluid levels, hose condition, brake linings), and well-trained operators following safe working practices are all indispensable. Communication between the bridge and the deck crew during retrieval is paramount.

The Marine Hydraulic Anchor Windlass is far more than just a winch; it's a sophisticated safety system engineered for one of the deck's most demanding tasks. By harnessing the smooth, controllable power of hydraulics, integrating robust mechanical brakes, and providing precise operational control, it enables crews to retrieve heavy anchors from challenging seabeds reliably and, most importantly, safely. This combination of power, control, and integrated safety features makes the hydraulic windlass the trusted choice for safe anchor handling on vessels worldwide, safeguarding crew, vessel, and equipment during this critical operation.

English

English  عربى

عربى  中文简体

中文简体