How a Marine Hydraulic Anchor Windlass Enhances Anchoring Safety for Large Vessels

2025.05.23

2025.05.23

Industry News

Industry News

Anchoring is one of the most critical operations for large vessels, requiring precision, power, and reliability. In challenging maritime environments, the Marine Hydraulic Anchor Windlass has emerged as a cornerstone technology for improving safety and operational efficiency.

The Role of a Marine Hydraulic Anchor Windlass

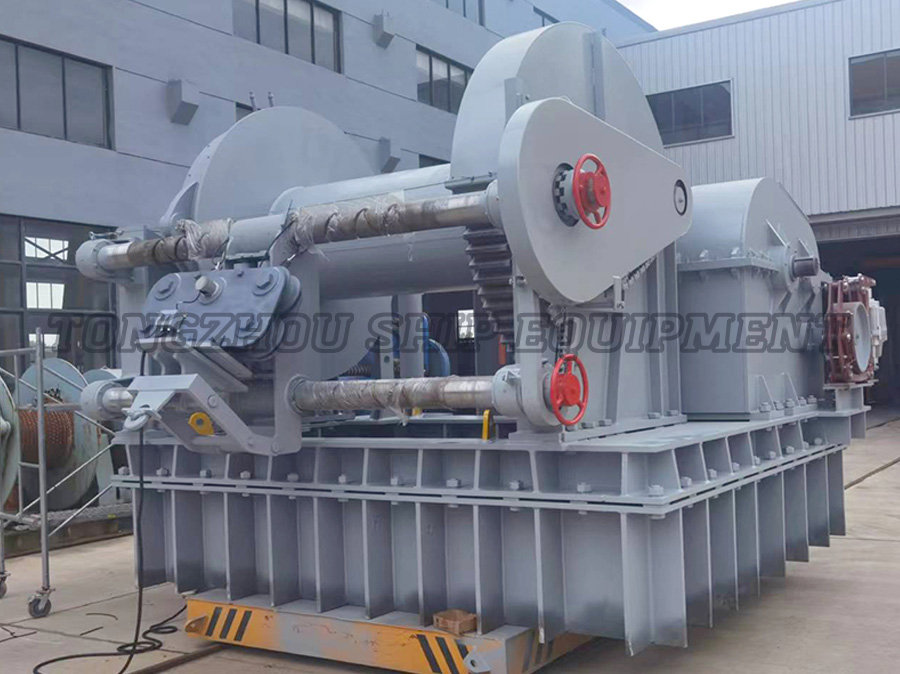

A Marine Hydraulic Anchor Windlass is a heavy-duty mechanical system designed to deploy, retrieve, and secure anchors and chains on ships. Unlike traditional electric or manual systems, it utilizes hydraulic power to generate the immense force required to handle anchors weighing several tons. Hydraulic systems are favored for their durability, consistent performance under load, and resistance to harsh marine conditions such as saltwater corrosion and extreme temperatures.

Key Safety Advantages

Controlled Load Management: Large vessels, such as cargo ships and tankers, rely on anchors that can weigh over 10 tons, with chains exceeding 100 meters in length. Hydraulic windlasses provide precise control over deployment and retrieval speeds, minimizing the risk of sudden chain slippage or uncontrolled drops that could damage equipment or endanger crew.

High Torque with Fail-Safe Mechanisms: Hydraulic systems deliver high torque at low speeds, ensuring smooth operation even under maximum load. Integrated safety features, such as pressure relief valves and automatic braking systems, prevent overload scenarios—a common cause of anchor equipment failure.

Reduced Human Error: Automated controls and remote operation capabilities allow crews to manage anchoring procedures from the bridge, reducing manual handling risks. Sensors and monitoring systems provide real-time feedback on chain tension, anchor position, and system health, enabling proactive adjustments.

Durability in Harsh Conditions: The sealed design of hydraulic components protects against water ingress and corrosion, critical for equipment exposed to seawater. This reliability reduces the likelihood of mechanical failures during critical anchoring maneuvers, especially in rough seas.

Industry Impact and Regulatory Compliance

The International Maritime Organization (IMO) and classification societies such as Lloyd’s Register emphasize the importance of robust anchoring systems for vessel safety. Modern Marine Hydraulic Anchor Windlasses comply with stringent standards like ISO 7825 and SOLAS (Safety of Life at Sea), ensuring they meet global safety benchmarks. Shipping companies report fewer anchor-related incidents and reduced downtime after upgrading to hydraulic systems, citing their ability to maintain performance over extended service periods.

Future Developments

Manufacturers are integrating smart technologies into hydraulic windlasses, including predictive maintenance algorithms and AI-driven load analytics. These innovations aim to further minimize human intervention while maximizing operational safety.

The Marine Hydraulic Anchor Windlass represents a vital evolution in maritime safety engineering. By combining power, precision, and resilience, it addresses the unique challenges of anchoring large vessels, safeguarding both crew and cargo. As shipping continues to prioritize safety and efficiency, this technology will remain indispensable for navigating the world’s waterways with confidence.

English

English  عربى

عربى  中文简体

中文简体