How Does Emergency Release Function on a Marine Hydraulic Anchor Windlass?

2025.07.11

2025.07.11

Industry News

Industry News

For any vessel reliant on a hydraulic anchor windlass, the smooth deployment and retrieval of the anchor is fundamental to safe operations. But what happens when the primary hydraulic system fails at a critical moment, potentially leaving the anchor stuck or the vessel vulnerable? This is where the Emergency Release Function proves its worth as an indispensable safety feature. Understanding its operation is not just technical knowledge; it's a vital aspect of maritime preparedness.

The Critical Need: When Hydraulics Fail

Hydraulic windlasses are robust, but failures can occur due to power loss (engine/generator failure), hydraulic fluid leaks, pump malfunction, or valve blockages. If such a failure happens while the anchor is being heaved in – especially if it's fouled on an obstruction or the seabed – the vessel could be immobilized in a hazardous location. Similarly, if the anchor is partially deployed and needs rapid release in an emergency (like sudden drift towards danger), the inability to disengage it quickly could be disastrous. The emergency release function provides a vital mechanical or hydraulic bypass to override the primary system.

Mechanisms of Emergency Release: Two Common Approaches

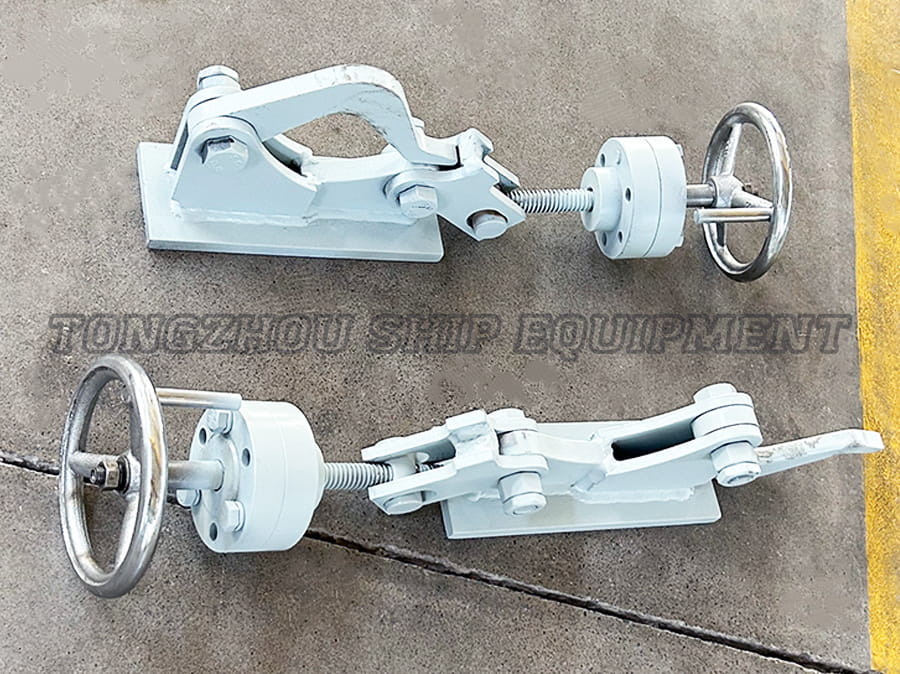

The specific design varies by manufacturer and model, but the core principle remains: providing a means to mechanically disengage the windlass gears or bypass the hydraulic system to allow the anchor chain to run freely under controlled conditions. Two primary methods are prevalent:

-

Mechanical Disengagement (Dog Clutch Release):

- How it Works: This system utilizes a mechanical clutch (often called a "dog clutch") connecting the hydraulic motor to the gypsy wheel or wildcat (the part that grips the chain). Under normal operation, this clutch is engaged, transmitting power.

- Activation: In an emergency, a dedicated, usually manual, lever or handle is operated. This physically disengages the dog clutch.

- Result: Once disengaged, the connection between the hydraulic motor and the chain gypsy is broken. The gypsy wheel is now free to rotate. Gravity acting on the anchor and chain will cause them to run out freely ("pay out") unless the chain brake is applied. Crucially, the chain brake must be used to control the speed of descent and finally stop the chain once the anchor is safely on the seabed or the desired length is paid out.

-

Hydraulic Bypass (Accumulator or Manual Valve Release):

- How it Works: Some systems rely on a hydraulic accumulator – a pressure storage reservoir charged by the main hydraulic system during normal operation.

- Activation: Operating an emergency release valve (often a manual lever-operated valve) redirects stored hydraulic fluid from the accumulator. This fluid is directed to release the holding brake(s) on the windlass shaft or directly actuate a mechanism to free the chain.

- Result: Releasing the brake allows the anchor and chain to run out under their own weight. Again, controlled descent using the chain brake is essential.

- Alternative Bypass: Systems without accumulators may use a manual valve that, when opened, simply relieves hydraulic pressure holding a brake or clutch in the engaged position, achieving the same result – allowing free-fall controlled by the chain brake.

Operational Imperatives and Precautions

Understanding how it works is only half the story. Knowing when and how safely to use it is critical:

- Last Resort: Emergency release is strictly for situations where the primary hydraulic system is inoperable and immediate anchor release is necessary for safety. It should never be used for routine anchoring or weighing anchor operations.

- Chain Brake is Paramount: Both methods above rely on the chain brake to control the descent. Attempting emergency release without ensuring the chain brake is functional and ready to be applied is extremely dangerous. Uncontrolled free-fall can damage the windlass, the chain, the hawsepipe, and pose severe risks to personnel.

- Controlled Descent: Once released, the chain brake must be carefully and progressively applied to manage the speed at which the chain runs out. Sudden, full application can cause shock loads and damage.

- Know Your System: Every windlass model is different. Crew members must be thoroughly trained on the specific location, operation, and procedures for the emergency release on their vessel's equipment. Regular drills are essential.

- Pre-Use Checks: Regular inspection and testing (according to manufacturer guidelines and safety procedures) of the emergency release mechanism, the chain brake, and associated linkages/valves are vital to ensure functionality when needed. This includes checking accumulator pre-charge pressure if applicable.

- Potential for Damage: Using emergency release, especially under load, can impose significant stress on the windlass structure and components. A post-release inspection by qualified personnel is highly recommended.

The emergency release function on a hydraulic anchor windlass is a fundamental safety mechanism, designed to provide a crucial last line of defense against becoming immobilized or unable to release an anchor in an emergency. Whether through mechanical disengagement or hydraulic bypass, its purpose is clear: to allow the anchor chain to run free when primary power is lost. However, its power demands respect. Its safe and effective use hinges entirely on thorough crew training, rigorous pre-use checks, meticulous maintenance, and, above all, the disciplined and controlled application of the chain brake. Understanding this function isn't just technical competence; it's a core component of responsible seamanship and vessel safety.

English

English  عربى

عربى  中文简体

中文简体