How to Select the Best Marine Windlass for Different Sea Conditions: A Guide for Safe and Efficient Anchoring

2025.05.16

2025.05.16

Industry News

Industry News

Selecting the right marine windlass is a critical decision for vessel owners, operators, and maritime professionals. A marine windlass—the mechanical powerhouse responsible for deploying, retrieving, and securing anchors—must perform reliably under diverse sea conditions. From calm harbors to storm-tossed open waters, the choice of windlass impacts safety, operational efficiency, and long-term durability. Here’s how to navigate the selection process with precision.

1. Assess Sea Conditions and Vessel Requirements

The first step in choosing a marine windlass is understanding the environments your vessel will encounter.

Calm Inland Waters: For lakes, rivers, or sheltered bays, lightweight aluminum or stainless-steel windlasses with moderate pulling power (e.g., 500–1,500 lbs) are sufficient. Electrically driven models are cost-effective and low-maintenance for these conditions.

Coastal and Nearshore Waters: Higher wave action and tidal currents demand corrosion-resistant materials like 316-grade stainless steel or hot-dipped galvanized steel. Look for windlasses with 2,000–4,000 lbs of pulling force and dual-speed motors to handle variable loads.

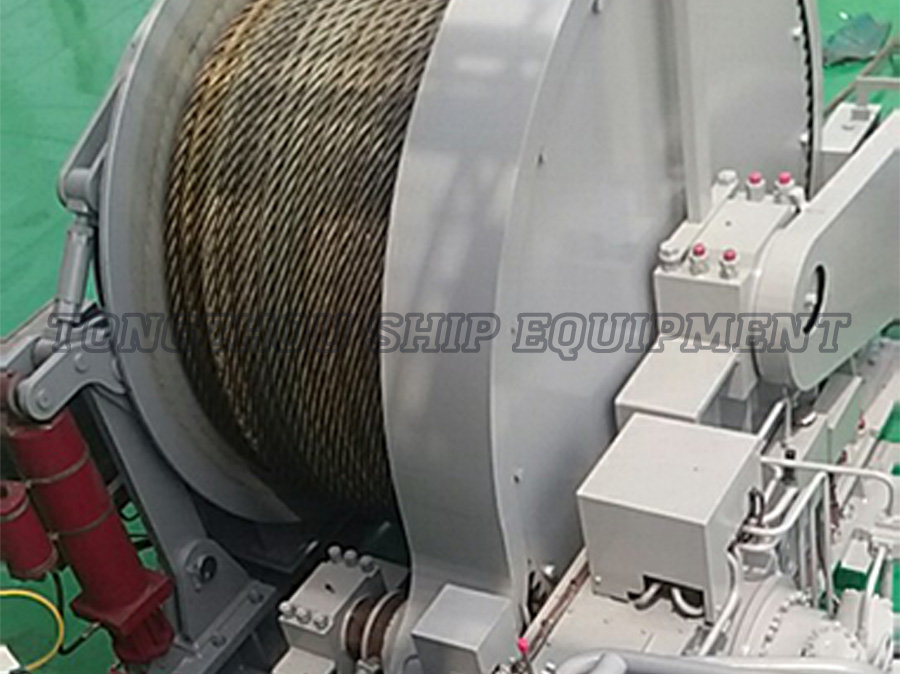

Offshore and Rough Seas: For blue-water cruising or commercial vessels, prioritize heavy-duty vertical or horizontal windlasses with 5,000+ lbs of pull capacity. Hydraulic systems are ideal here, offering unmatched power and reliability in extreme conditions.

Polar or High-Salt Environments: Opt for specialized marine windlasses with antifreeze lubrication, sealed gears, and advanced coatings to combat ice, salt corrosion, and subzero temperatures.

2. Material Matters: Durability in Harsh Environments

The marine windlass’s construction determines its lifespan. Saltwater, UV exposure, and mechanical stress require robust materials:

Stainless Steel: Best for corrosion resistance in saltwater.

Hot-Dipped Galvanized Steel: A budget-friendly option for nearshore use.

Aluminum Alloys: Lightweight but durable for sailboats or yachts prioritizing weight savings.

3. Power Source: Electric vs. Hydraulic

Electric Windlasses: Compact, easy to install, and suitable for most recreational boats. Ensure the battery system can handle peak loads.

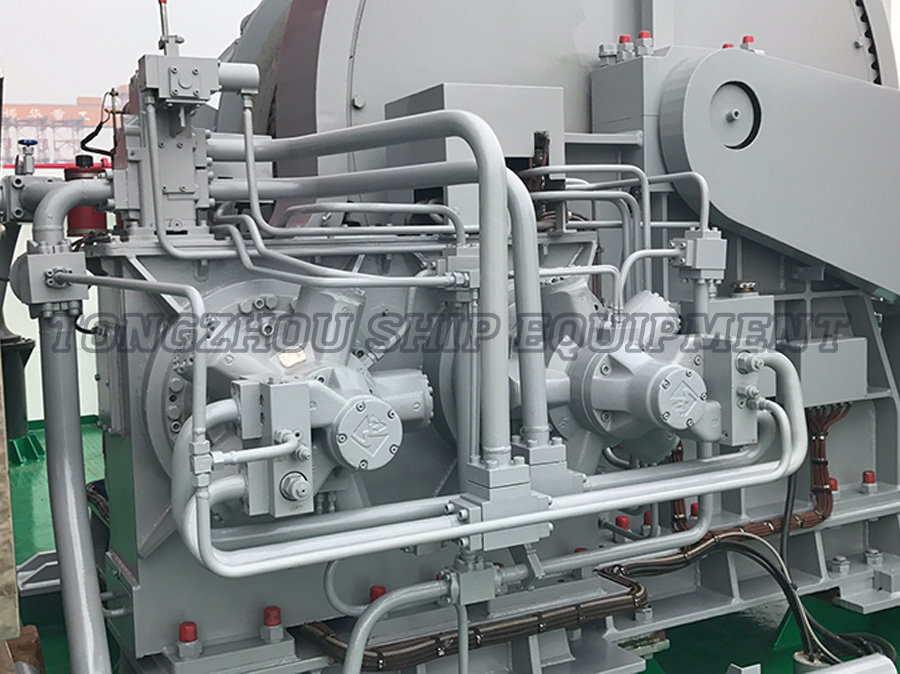

Hydraulic Windlasses: Preferred for commercial or large vessels. They deliver consistent power in rough seas but require a hydraulic pump and hoses.

4. Chain and Rode Compatibility

A marine windlass must align with your anchor chain’s diameter and type (e.g., BBB, ACCO, or metric chains). Mismatched gypsies (chain wheels) can cause slippage or jamming. For mixed rode systems (chain + rope), select a windlass with a combined wildcat and rope drum.

5. Load Capacity and Speed

Calculate the total load: anchor weight + chain + expected drag force. Oversizing by 20–30% ensures safety margins. For example, a 50 lb anchor with 200 feet of chain in rough seas may require a windlass rated for 1,800–2,200 lbs. Variable-speed motors add precision in challenging retrievals.

6. Safety and Redundancy Features

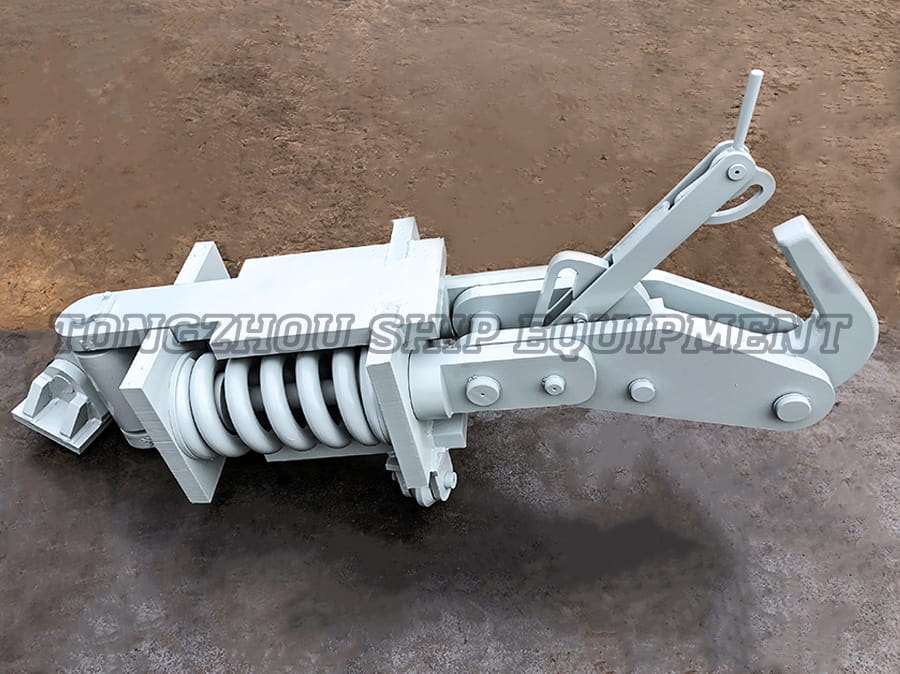

Emergency Release: Critical for quick anchor detachment in emergencies.

Waterproofing: IP67 or higher ratings protect against submersion.

Manual Override: A backup crank ensures functionality if power fails.

Consult naval engineers or marine technicians to match the windlass to your vessel’s specifications. Remember: A high-quality marine windlass is an investment in safety—never compromise on reliability when facing unpredictable seas.

By prioritizing environment-specific features, material resilience, and load capacity, you can anchor with confidence, no matter the conditions.

English

English  عربى

عربى  中文简体

中文简体