What are common Hydraulic Windlass troubleshooting tips?

2025.08.29

2025.08.29

Industry News

Industry News

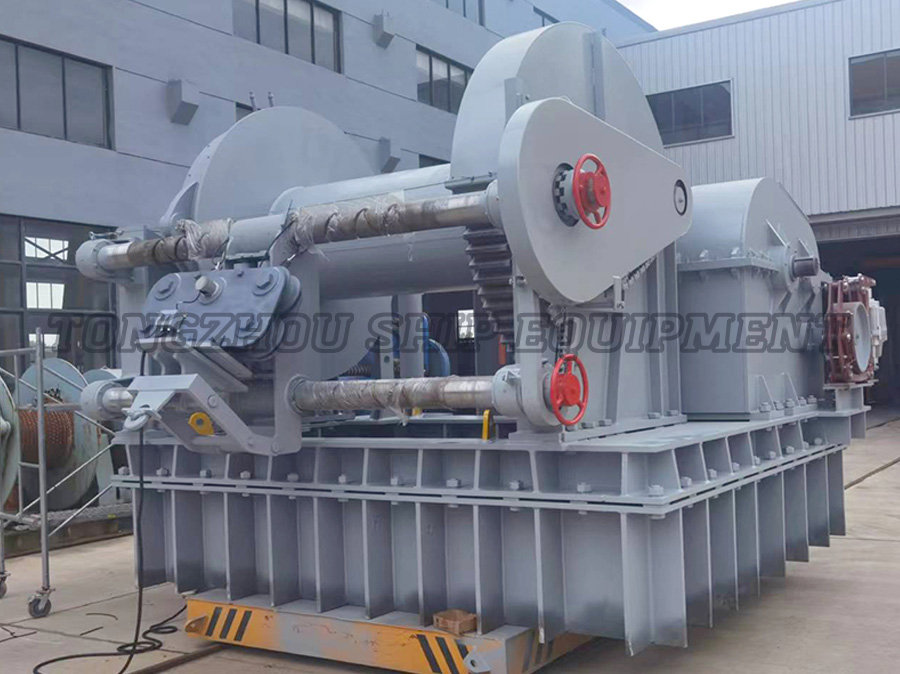

A reliable anchoring system is a critical component of vessel safety, and the Hydraulic Windlass serves as its core. Proper operation is essential for secure anchoring and mooring. However, like all marine equipment, a Hydraulic Windlass can experience issues that hinder its performance.

A methodical troubleshooting process, prioritizing safety and starting with the simplest solutions, is the most effective path to restoring functionality.

1. Addressing Hydraulic Oil and Flow Issues

The most frequent problems with a Hydraulic Windlass originate from the hydraulic system itself.

-

Symptom: Slow or Weak Operation; Inability to Lift Load

-

Check Hydraulic Oil Level: Inspect the reservoir of the power unit. A low oil level will cause cavitation, where the pump sucks air instead of oil, leading to a loss of power and potential pump damage.

-

Inspect Oil Condition: The oil must be clean and of the correct type. Cloudy, milky, or foamy oil indicates water contamination or aeration, which reduces lubrication and system efficiency. Dark, viscous oil suggests overheating or breakdown. Contaminated oil can damage pumps, motors, and valves.

-

Verify Pump Drive Belt: On systems with a belt-driven pump, a loose or worn belt will slip under load, resulting in reduced RPM and poor performance. Check tension and condition.

-

Check System Pressure: Using a hydraulic pressure gauge, test the pressure at the windlass inlet against the manufacturer's specifications. Low pressure indicates a problem with the pump, a pressure relief valve that is stuck open, or a significant internal leak.

-

-

Symptom: Windlass Operates Erratically or Not at All

-

Check Control Circuit: For electric-over-hydraulic systems, ensure the control solenoid is receiving power. A failed solenoid valve will prevent hydraulic flow from reaching the windlass motor. Listen for an audible "click" when the control is activated.

-

Bleed the System: Air trapped in the hydraulic lines can cause spongy, erratic operation. Consult the manufacturer's manual for the correct bleeding procedure, which typically involves loosening a fitting at the highest point of the system while running the pump.

-

2. Troubleshooting Motor and Mechanical Linkages

If the hydraulic supply is confirmed to be adequate, the issue may lie within the windlass itself.

-

Symptom: Motor Humms but Does Turn, or Turns Very Slowly

-

This strongly suggests an internal mechanical fault. Immediately cease operation to prevent further damage.

-

Check for Obstructions: Visually inspect the gypsywildcat and chain locker for jammed links, twisted chain, or foreign objects obstructing the gear train.

-

Internal Damage: Worn gears, bearings, or a damaged motor itself can create excessive internal friction, preventing the motor from turning even with sufficient oil pressure. This requires disassembly by a qualified technician.

-

-

Symptom: Excessive Noise During Operation (Grinding, Knocking)

-

Lubrication: Many Hydraulic Windlass units have external grease points for the gypsy shaft and bearings. Failure to lubricate according to the service schedule leads to metal-on-metal wear and noise.

-

Loose Mounting Bolts: Vibration can loosen the foundation bolts securing the windlass to the deck. This is a critical safety check, as a loose unit can lead to catastrophic failure under load.

-

3. Resolving Operational and Control Problems

-

Symptom: Windlass Fails to Hold Load; Chain Slipping

-

Adjust the Brake: Most hydraulic windlasses have an external brake band or an internal brake mechanism. Over time, these wear and require adjustment per the manufacturer's instructions to maintain holding power.

-

Worn Wildcat/Gypsy: A severely worn gypsy will not properly engage the chain links, causing the chain to jump or slip under strain. Compare the gypsy profile to a new chain link for wear.

-

-

Symptom: Remote Control is Unresponsive

-

Check Electrical Connections: For remote controls, inspect for corroded terminals, broken wires, or blown fuses in the control circuit.

-

Test at Local Manifold: If the remote fails, attempt to operate the windlass directly at the local hydraulic control valve manifold (if equipped). If it works locally, the problem is isolated to the remote control system.

-

Effective Hydraulic Windlass troubleshooting is a process of elimination. Start by verifying the quality and supply of hydraulic oil, then proceed to check electrical controls, and finally inspect the mechanical components of the unit itself. Adherence to a regular preventive maintenance schedule—including oil analysis, filter changes, and lubrication—is the most effective strategy for minimizing downtime and ensuring the long-term reliability of your Hydraulic Windlass system.

English

English  عربى

عربى  中文简体

中文简体