How to Choose the Right Hydraulic Windlass for Your Vessel?

2025.09.05

2025.09.05

Industry News

Industry News

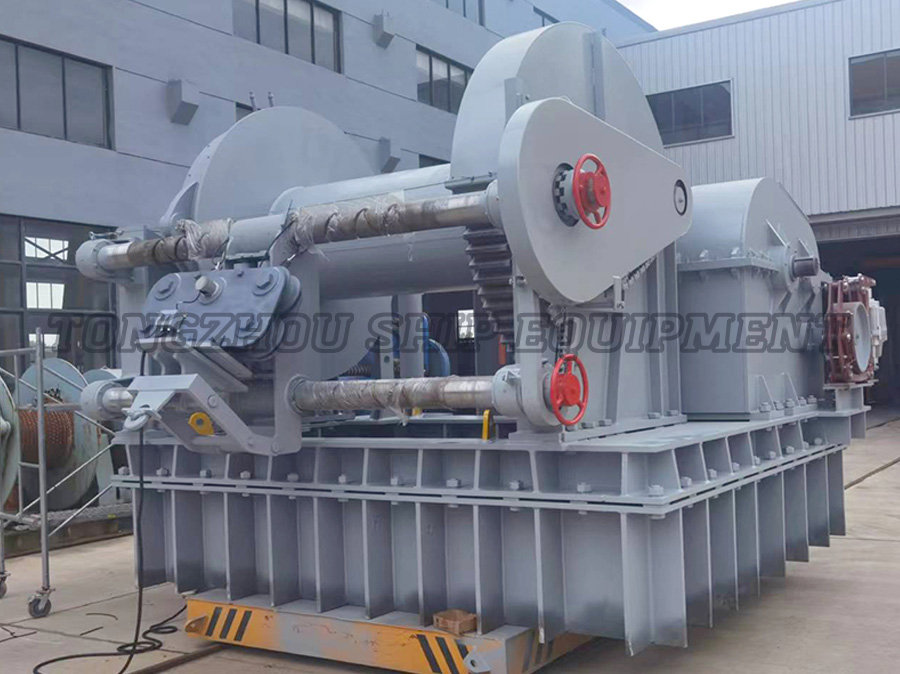

Selecting the right equipment for a vessel is a critical decision that impacts safety, functionality, and operational efficiency. Among these key components, the Hydraulic Windlass serves as the primary workhorse for anchor handling. Choosing the correct one requires a methodical assessment of several technical factors specific to your vessel and its intended use.

1. Assess Your Vessel's Specifications

The first step is to gather precise data about your boat. The most critical metrics are:

-

Boat Length and Displacement: Heavier and longer vessels require a windlass with higher pulling power.

-

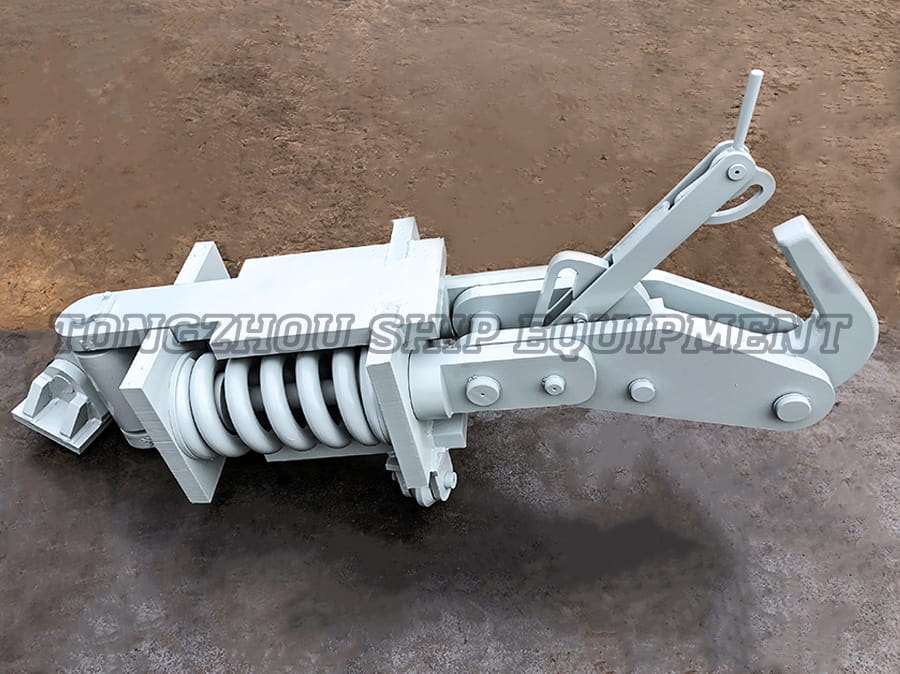

Anchor Rode Type and Size: Determine the type (chain, rope, or a combination) and the exact diameter of your chain and rope. The Hydraulic Windlass must be equipped with a wildcat (chain gypsy) that is precisely machined to fit your chain's gauge and grade.

-

Depth of Operation: Consider the typical water depths in which you will anchor. This influences the amount of rode to be retrieved and the load on the system.

2. Calculate Required Performance

With your vessel's data, you can determine the necessary performance of the Hydraulic Windlass.

-

Working Load: This is the typical load the windlass will handle during standard anchoring. A general rule is to calculate the total weight of your anchor and rode in the water, but a more critical metric is the holding power required.

-

Holding Load and Breakaway Force: The windlass must be powerful enough to overcome the initial "breakout" force required to free the anchor from the seabed, which is significantly higher than the retrieval load. Manufacturers provide rated holding and retrieval loads for their models; ensure these exceed your calculated requirements with a sufficient safety margin.

3. Evaluate Hydraulic System Compatibility

A Hydraulic Windlass is part of a larger system. Compatibility is paramount.

-

Hydraulic Flow and Pressure: Check your vessel's existing hydraulic system's output in terms of flow (liters per minute or gallons per minute) and pressure (bar or PSI). The chosen windlass must operate efficiently within these parameters. An undersized pump will result in slow operation, while excessive pressure can damage the windlass motor.

-

Motor Type: Ensure the windlass motor is matched to your system's pressure rating. Installing a dedicated pump for the windlass may be necessary if the current system lacks capacity.

4. Consider Design and Installation Factors

-

Deck Layout and Mounting: The windlass must fit the available space on the foredeck. Measurements for the base footprint, shaft length, and hawsepipe alignment are crucial. Decisions must be made between vertical or horizontal shaft models based on deck configuration and rode storage below.

-

Remote Control: Consider the placement of control switches. Options typically include foot switches at the bow, handheld remotes, and control from the helm. Each offers different advantages for operational safety and convenience.

5. Prioritize Quality and Maintenance

-

Construction Materials: Given the harsh marine environment, look for components constructed from corrosion-resistant materials such as stainless steel, anodized aluminum, or high-tensile bronze.

-

Ease of Maintenance: Access for routine inspection and service is important. Review the design for ease of greasing seals and checking for wear on moving parts.

Choosing the right Hydraulic Windlass is an engineering decision based on a vessel's specific physical characteristics and operational profile. By systematically evaluating vessel specifications, calculating performance needs, ensuring hydraulic compatibility, and reviewing installation requirements, a vessel owner or operator can make a informed selection. The result is a reliable and durable system that enhances safety and simplifies the anchoring process for years to come.

English

English  عربى

عربى  中文简体

中文简体