Why is a Hydraulic Windlass better than an electric windlass when choosing anchoring equipment for your vessel?

2025.10.04

2025.10.04

Industry News

Industry News

Selecting appropriate anchoring equipment is critical for vessel safety and operational efficiency in marine environments. Among the key components, the windlass plays a vital role in anchor handling, and the choice between hydraulic and electric systems can significantly impact performance.

Types of Anchoring Equipment

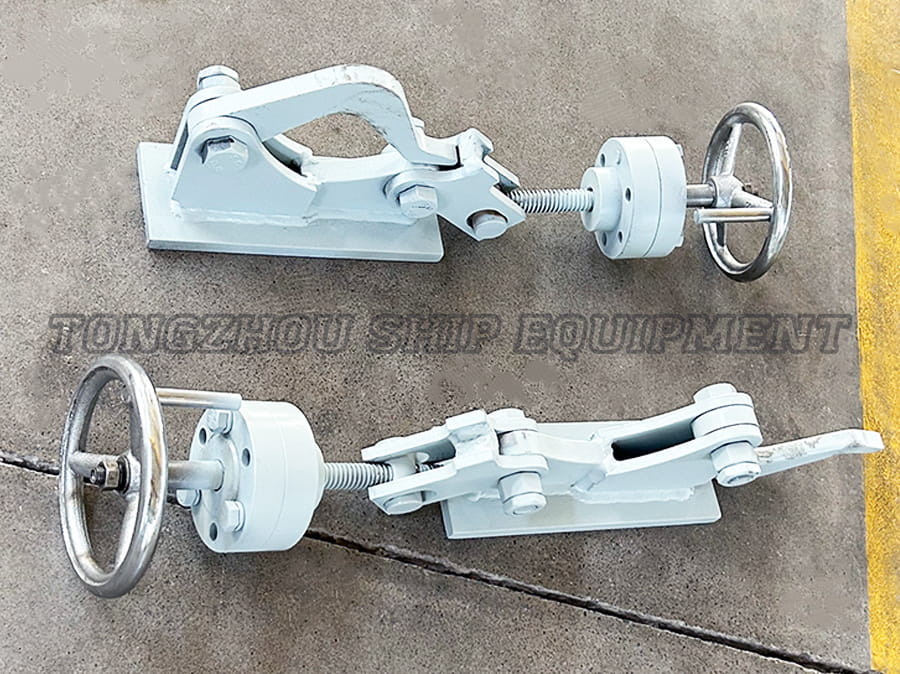

Anchoring systems primarily consist of windlasses, which are classified by their power source. A Hydraulic Windlass operates using hydraulic fluid pressure, typically driven by a vessel's hydraulic system. In contrast, an electric windlass relies on electrical motors for power. Both types are designed to handle anchor chains or ropes, but their mechanisms differ in complexity and energy conversion. Other variations include manual windlasses, though these are less common in modern commercial and large recreational vessels due to efficiency demands.

Applications of Windlasses

Windlasses are essential for various marine vessels, including commercial ships, yachts, and offshore platforms. A Hydraulic Windlass is commonly employed in harsh environments, such as heavy-duty commercial operations or areas with high moisture and corrosion risks, due to its robust design. Electric windlasses are often found in smaller vessels or calmer waters where power demands are lower. The application choice depends on factors like vessel size, operating conditions, and load requirements, with hydraulic systems favored for high-torque needs.

Comparison: Hydraulic Windlass vs. Electric Windlass

A comparative analysis highlights the advantages of a Hydraulic Windlass based on technical parameters:

-

Power and Torque: Hydraulic Windlasses deliver higher torque and consistent power output, making them suitable for heavy anchors and deep-water operations. Electric windlasses may experience power drops under high loads.

-

Durability and Maintenance: Hydraulic systems are sealed, reducing exposure to water and corrosion, which extends service life. Electric windlasses require more frequent maintenance in moist conditions due to electrical component vulnerability.

-

Efficiency and Response: Hydraulic Windlasses provide smooth operation and rapid response under load, with less risk of overheating. Electric models can overheat in prolonged use, potentially leading to downtime.

-

Environmental Adaptability: Hydraulic Windlasses perform reliably in extreme temperatures and wet environments, as hydraulic fluids are less affected by external conditions. Electric systems may face issues with insulation and short circuits in humid settings.

-

Cost Considerations: While initial costs for a Hydraulic Windlass may be higher, its longevity and reduced maintenance can lead to lower lifetime expenses compared to electric windlasses, which might incur more replacement parts costs.

This comparison is derived from engineering studies and marine equipment standards, emphasizing functional differences without subjective bias.

Frequently Asked Questions (FAQ)

-

What is a Hydraulic Windlass?

A Hydraulic Windlass is a mechanical device that uses hydraulic pressure to raise and lower anchors, offering high power and reliability for marine applications. -

Why choose a Hydraulic Windlass over an electric one?

Based on operational data, a Hydraulic Windlass excels in demanding conditions due to its superior torque, durability, and minimal electrical failure risks. -

Is a Hydraulic Windlass suitable for all vessel types?

It is most beneficial for larger vessels or those in rough seas, but suitability depends on specific design requirements and power availability. -

How does maintenance differ between hydraulic and electric windlasses?

Hydraulic Windlasses require periodic fluid checks and seal inspections, while electric windlasses need more attention to motors and wiring to prevent moisture damage. -

Can a Hydraulic Windlass be retrofitted onto existing vessels?

Yes, but it involves integrating with the vessel's hydraulic system, which may require professional assessment for compatibility.

English

English  عربى

عربى  中文简体

中文简体