How does the Hydraulic Windlass work?

2025.09.26

2025.09.26

Industry News

Industry News

The hydraulic windlass is a critical component in maritime operations, serving as the primary device for anchor handling on various vessels. Understanding its working principle is essential for professionals in the shipping and offshore industries.

Working Principle of a Hydraulic Windlass

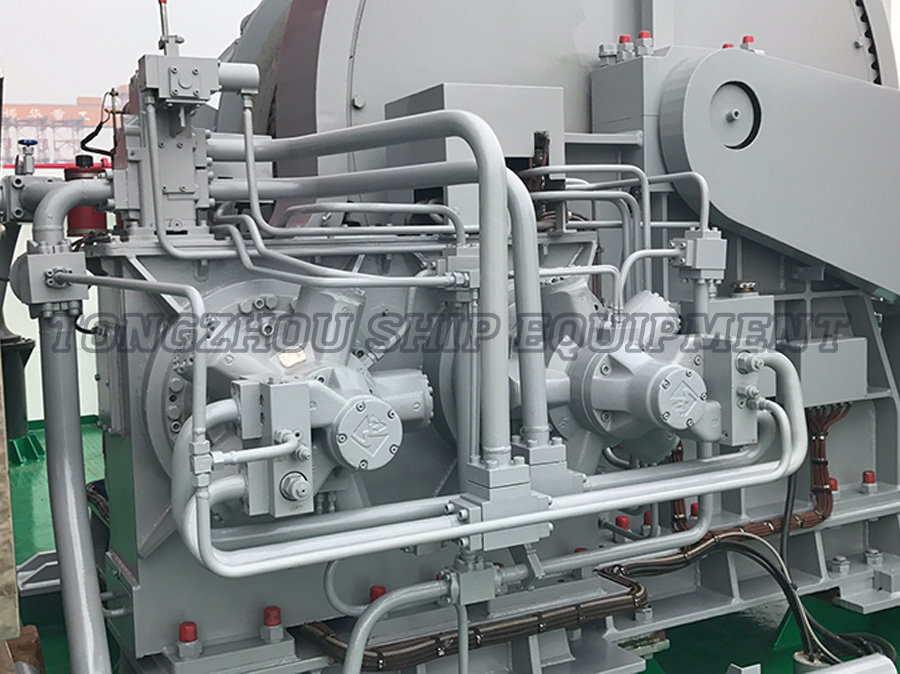

A hydraulic windlass operates using a hydraulic system to transmit power for raising and lowering anchors and chains. The core mechanism involves a hydraulic motor driven by pressurized fluid, typically oil, which is supplied by a hydraulic pump. This pump is often powered by the vessel's main engine or an auxiliary power unit. The hydraulic motor converts the fluid's pressure into rotational torque, which then drives a gearbox or directly engages with the chain wheel. As the wheel rotates, it manages the anchor chain or rope, allowing for controlled deployment or retrieval. Key components include control valves for direction and speed regulation, relief valves for safety, and a braking system to secure the anchor when not in motion. The efficiency of a hydraulic windlass relies on factors such as fluid viscosity, pressure ratings, and system maintenance.

Types of Hydraulic Windlasses

Hydraulic windlasses are categorized based on design and installation requirements. Common types include horizontal windlasses, which feature a horizontal axis for the chain wheel and are suitable for vessels with limited deck space. Vertical windlasses have a vertical axis and are often used on larger ships due to their higher load capacity. Additionally, there are combined windlasses that integrate both anchor handling and mooring functions. Variations may also exist in terms of drive mechanisms, such as direct-driven or gear-driven systems, each offering specific advantages in torque and durability.

Applications of Hydraulic Windlasses

Hydraulic windlasses are predominantly employed in maritime settings where reliability and high torque are crucial. They are found on commercial ships, such as cargo vessels, tankers, and cruise liners, as well as on offshore platforms and fishing boats. Their ability to function effectively in harsh environments, including extreme weather and heavy loads, makes them ideal for deep-sea operations. In addition to anchor handling, some hydraulic windlasses are adapted for towing or winching applications, demonstrating versatility in marine engineering.

Comparison with Other Windlass Types

When comparing hydraulic windlasses to alternative types, such as electric windlasses, several factors come into play. Hydraulic systems generally offer higher torque output and better overload protection, making them suitable for heavy-duty use. They are less prone to electrical failures and can operate efficiently in wet conditions. However, hydraulic windlasses may require more complex installation and maintenance due to hydraulic fluid handling. In contrast, electric windlasses are often simpler to install but might have limitations in continuous heavy loading. The choice between types depends on vessel size, operational requirements, and environmental considerations.

Frequently Asked Questions (FAQ)

What maintenance is required for a hydraulic windlass?

Regular maintenance includes checking hydraulic fluid levels, inspecting hoses and seals for leaks, and ensuring valves and motors are clean and functional. Periodic pressure tests and fluid changes are recommended to prevent failures.

How does a hydraulic windlass handle safety concerns?

Safety features often include pressure relief valves to prevent overloading, mechanical brakes for secure holding, and emergency stop controls. Operators should follow standardized procedures for safe operation.

What are the efficiency considerations for a hydraulic windlass?

Efficiency is influenced by hydraulic system design, with factors like pump efficiency and pressure losses affecting performance. Proper sizing based on vessel needs can optimize energy use.

Can a hydraulic windlass be used in small boats?

While more common on larger vessels, compact hydraulic windlasses are available for smaller boats, though electric options might be more cost-effective for light-duty applications.

The hydraulic windlass remains a vital tool in maritime operations, leveraging hydraulic power for reliable anchor management.

English

English  عربى

عربى  中文简体

中文简体