How does a hydraulic windlass work?

2025.09.12

2025.09.12

Industry News

Industry News

The operation of a hydraulic windlass begins with a power source, typically the vessel’s main engine or a dedicated auxiliary engine. This engine drives a hydraulic pump, which is the heart of the system. The pump converts mechanical energy into hydraulic energy by pressurizing a specialized oil fluid. This high-pressure fluid is then transmitted through reinforced hoses to a hydraulic motor mounted within the windlass unit.

Key Components and Their Functions

-

Hydraulic Pump: Located near the vessel's engine, the pump generates the flow and pressure required to drive the system. It is often a variable displacement pump, allowing the operator to control the speed and torque of the windlass by adjusting the fluid flow.

-

Hydraulic Motor: The pressurized fluid from the pump is directed to the hydraulic motor. This motor acts as the prime mover of the windlass, converting the hydraulic energy back into mechanical rotation. The torque produced by the motor is significantly high, which is essential for lifting the immense weight of an anchor and its chain.

-

Gearbox: The rotational force from the hydraulic motor is fed into a reduction gearbox. This gearbox reduces the motor's high rotational speed to a much lower, more powerful output speed, increasing the torque available at the windlass shaft.

-

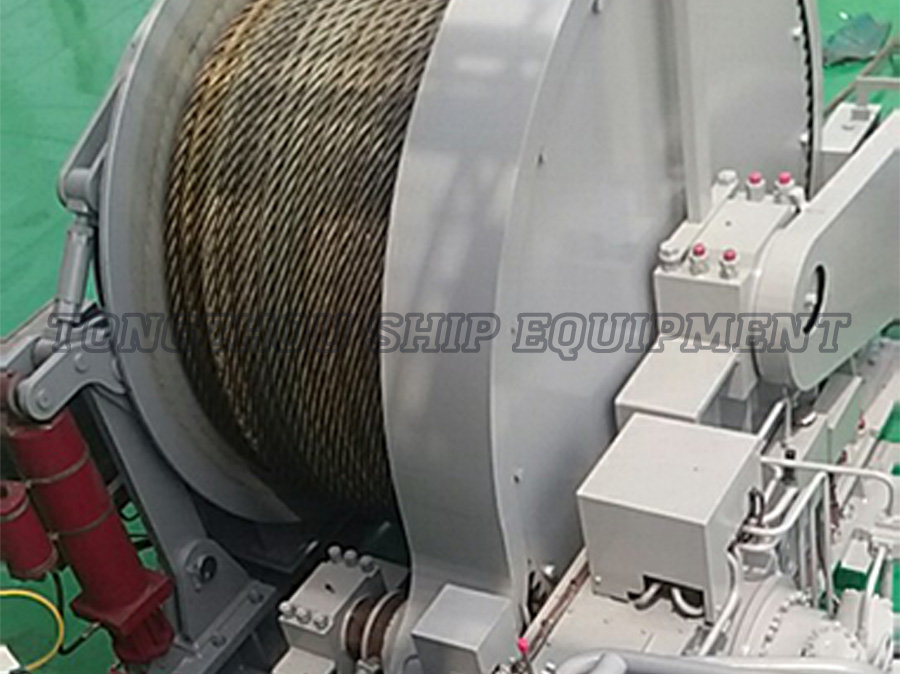

Chainwheel (Gypsy) and Warping Drum: The output shaft from the gearbox drives one or two key components:

-

The chainwheel or gypsy is a spoked wheel with shaped pockets that engage the links of the anchor chain. As it rotates, it hauls in or veers out the chain.

-

The warping drum is a smooth barrel used for handling mooring lines or ropes.

-

-

Clutch and Brake: A mechanical clutch is provided to disengage the chainwheel from the drive train. This allows the crew to freewheel the chainwheel for manual operation or to let the anchor run under its own weight. A separate brake band is applied to the chainwheel to control the speed of descent during anchoring and to securely hold the anchor and chain in place once deployed.

The Operational Workflow

The process of hauling anchor involves a coordinated sequence:

-

Engagement: The operator engages the mechanical clutch to connect the chainwheel to the drive system.

-

Control: From a remote control station, the operator activates the hydraulic system. Moving the control lever directs pressurized fluid to the hydraulic motor, causing it to rotate.

-

Hauling: The motor turns the gearbox, which drives the chainwheel. The chainwheel grips the chain and hauls it in, lifting the anchor from the seabed.

-

Stowage: Once the anchor is clear of the water and secured in the hawsepipe, the brake is applied, and the clutch is disengaged.

-

Pay-out: To lower the anchor, the clutch is engaged, and the brake is carefully released in a controlled manner, allowing the weight of the anchor and chain to drive the motor, which now acts as a pump. The system's relief valves manage the backpressure to control the rate of descent.

Advantages of a Hydraulic System

The hydraulic windlass offers several inherent advantages. The hydraulic motor is inherently sealed from its environment, making it highly resistant to corrosion and water ingress. The system provides smooth, continuous power with high torque even at very low speeds, which is crucial for controlled and safe anchoring. The hydraulic components can be located away from the windlass itself, allowing for a compact deck unit and flexible installation. Furthermore, the use of relief valves protects the system from overloads, preventing damage during operation.

A hydraulic windlass functions by transforming engine power into controlled hydraulic pressure, which drives a motor to provide the high-torque, low-speed mechanical force needed to handle heavy ground tackle. Its design prioritizes power, control, and durability, making it a standard and trusted system on a wide range of maritime vessels.

English

English  عربى

عربى  中文简体

中文简体