What is the difference between a hydraulic windlass and a anchor capstan?

2025.09.19

2025.09.19

Industry News

Industry News

In the maritime world, the safe and efficient handling of ground tackle—anchors, chains, and ropes—is paramount. Two fundamental pieces of equipment designed for this critical task are the windlass and the capstan. While often used interchangeably in casual conversation, they serve distinct purposes and possess different design characteristics.

Defining the Core Functions

What is a Hydraulic Windlass?

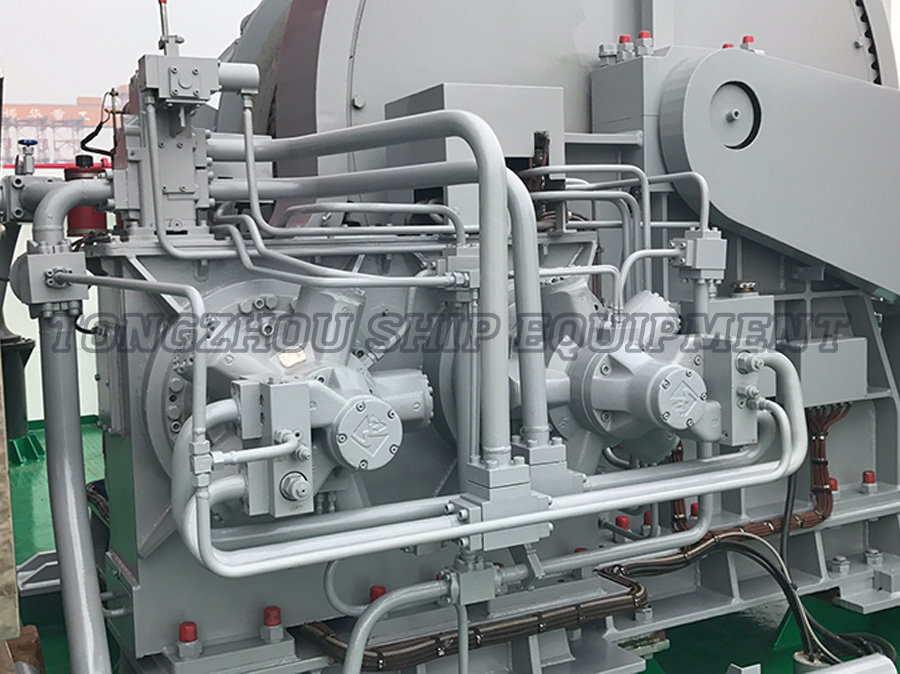

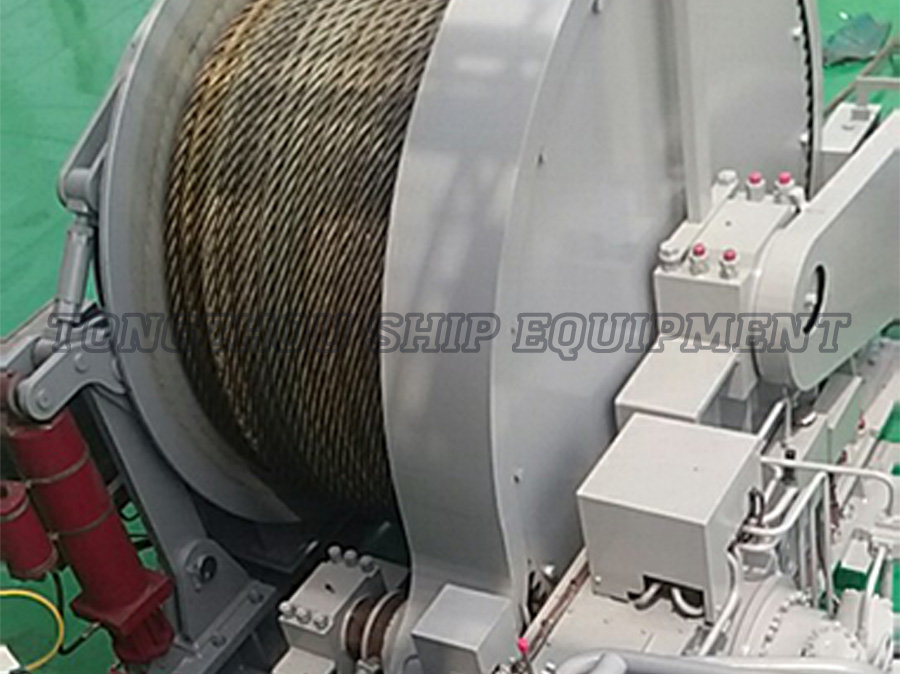

A hydraulic windlass is a deck machine specifically designed for the vertical hoisting (weighing) and lowering (dropping) of an anchor and its chain cable. Its primary function is to handle high loads in a direct, linear pull. The key component of a windlass is the wildcat (or chainwheel), a sprocketed drum engineered to engage the links of an anchor chain, providing a positive grip and efficient power transmission. The term hydraulic windlass specifies that the unit is powered by a hydraulic motor, which is favored for its high torque output, smooth operation, and reliability in demanding marine environments.

What is an Anchor Capstan?

An anchor capstan is a vertical-axis rotating machine used primarily for handling rope (line) or wire cable. Its cylindrical drum, or barrel, is designed to take multiple turns of a line, using friction to hold and haul it in. While a capstan can be used to assist in anchor retrieval by handling the rope/chain combination on smaller vessels, its core utility extends to mooring operations, warping (moving a ship in a dock), and hauling in fishing gear or other loads.

Types and Configurations

Windlass Types:

-

Horizontal Windlass: The shaft is mounted horizontally. This is the most common type on modern vessels, often featuring a wildcat on either end and a gypsy (a smaller, rope-handling drum) in the center.

-

Vertical Windlass: The shaft is mounted vertically, taking up less deck space but requiring more below-deck space for the machinery.

-

Combination Units: Many modern hydraulic windlass units are combination windlass/capstans, integrating one or two wildcats for chain with a capstan head (or gypsy) for handling rope.

Capstan Types:

-

Vertical Capstan: The standard design with a vertical drum.

-

Double Capstan: Features two drums on a single shaft to handle two lines simultaneously.

-

Warping Capstan: A specific type designed for moving a vessel along a dock, often featuring a horizontal head that can be engaged and disengaged.

Key Applications and Vessel Use

Hydraulic Windlass Application:

The hydraulic windlass is an indispensable piece of equipment on any vessel that uses a chain anchor rode. Its high pulling power and positive chain engagement make it ideal for:

-

Large commercial vessels (cargo ships, tankers, offshore supply vessels).

-

Superyachts and large sailing yachts.

-

Fishing vessels and naval ships.

Its application is almost exclusively dedicated to anchor work.

Anchor Capstan Application:

The capstan is a more versatile tool used for:

-

Mooring and docking operations on vessels of all sizes.

-

Handling fishing nets and lines on trawlers.

-

As a secondary aid on smaller craft with rope/chain rodes, where the rope is secured to a samson post and the capstan is used to haul the vessel forward to break the anchor out.

-

Traditional sailing vessels where manual capstans are used for a variety of hauling tasks.

Direct Comparison: Windlass vs. Capstan

| Feature | Hydraulic Windlass | Anchor Capstan |

|---|---|---|

| Primary Function | Handling anchor chain (vertical lift) | Handling rope (horizontal pull) |

| Load Handling | Direct, positive engagement via wildcat | Frictional engagement via line wrapped around drum |

| Axis of Rotation | Typically horizontal (shaft) | Typically vertical (drum) |

| Typical Power Source | Hydraulic, electric, pneumatic | Hydraulic, electric, manual |

| Key Component | Wildcat (Chainwheel) | Drum (Barrel) |

| Best Suited For | Dedicated anchor retrieval & lowering | Mooring, warping, versatile hauling |

Frequently Asked Questions (FAQ)

Q1: Can a capstan be used to raise an anchor?

Yes, but with significant limitations. A capstan can be used to raise an anchor on smaller vessels that use a combined rope and chain rode. The chain is typically brought aboard manually until the rope is reached, which is then wrapped around the capstan. However, it is not suitable for handling chain directly on its smooth drum and lacks the positive engagement and high hoisting power of a dedicated hydraulic windlass for all-chain rodes.

Q2: Why choose a hydraulic power system?

A hydraulic windlass offers several advantages:

-

High Torque: Hydraulic motors provide immense power and torque at low speeds, ideal for breaking an anchor out of the seabed.

-

Controlled Operation: Allows for smooth, precise control during lowering and hoisting.

-

Durability: Hydraulic systems are robust, often sealed, and perform well in wet, corrosive environments.

-

Safety: Can be designed to hold loads without continuous power application (e.g., via a hydraulic holding valve).

Q3: What is a "windlass with a capstan head"?

This is a combination unit, very common on midsize to large yachts and workboats. It integrates the primary function of a windlass (a wildcat for chain) with the versatile secondary function of a capstan (a vertical drum for rope). This allows the vessel to handle its anchor chain efficiently and also use the same power source for mooring lines.

Q4: How important is maintenance?

Critical. Both hydraulic windlass and capstan systems require regular maintenance. This includes checking hydraulic fluid levels and lines for leaks, inspecting seals, lubricating moving parts, and ensuring the chain wildcat is correctly aligned and matched to the chain size. Proper maintenance ensures reliability and safety, which are non-negotiable in marine operations.

The choice between a dedicated hydraulic windlass and an anchor capstan is not a matter of which is better, but rather which is appropriate for the specific application. The hydraulic windlass is the specialized powerhouse for anchor handling, designed for the extreme loads of all-chain systems. The capstan is the versatile tool for deck work, excels in line handling and mooring. Understanding their fundamental differences—the windlass for vertical lifting of chain and the capstan for horizontal pulling of rope—is essential for selecting the right equipment to ensure the safety, functionality, and efficiency of any vessel.

English

English  عربى

عربى  中文简体

中文简体