How Does an Electric Windlass Improve Anchoring Efficiency?

2026.01.23

2026.01.23

Industry News

Industry News

Anchoring is a vital part of maritime activities, ensuring that vessels stay in a desired location, whether at sea or in harbor. Traditionally, anchoring involved manual labor, but with the advent of modern technology, the Electric Windlass has revolutionized this process. This powerful device has significantly improved the speed, safety, and efficiency of anchoring operations.

What is an Electric Windlass?

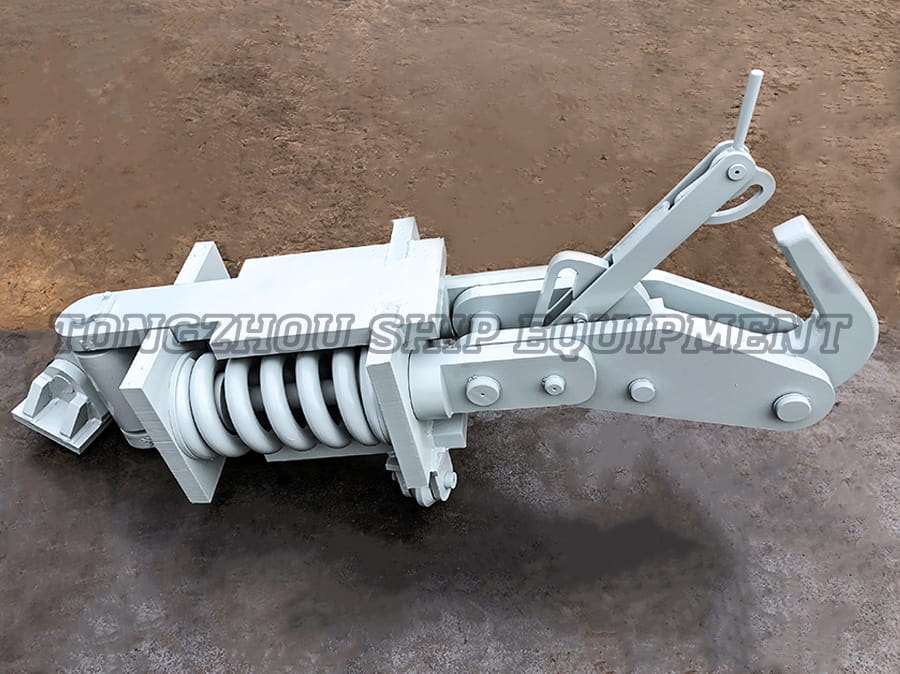

An Electric Windlass is an electrically powered mechanical device used to raise or lower an anchor. It consists of a motor that drives a gypsy (the part that holds the anchor chain) and a drum. This device is often mounted on the deck of a boat or ship and allows the operator to control the anchor from the comfort of the cabin or cockpit. The primary function of the windlass is to automate the process of raising or lowering the anchor, significantly reducing manual effort.

How Does an Electric Windlass Work?

The operation of an electric windlass is straightforward, thanks to its powerful motor and user-friendly controls. The electric motor is connected to the gypsy and drum, which are responsible for handling the anchor chain. By activating the windlass using a button or switch, the motor engages, turning the gypsy to pull in or release the anchor chain. The motor ensures that the anchor is either pulled up from the seabed or lowered with precision and control.

Most electric windlasses come with automatic features, such as chain counters or an auto-stop mechanism, which allow users to control how much chain is let out or pulled in, ensuring that the anchor is set at the right depth.

Benefits of Using an Electric Windlass

- Improved Efficiency: The most significant advantage of an electric windlass is the dramatic improvement in anchoring efficiency. With the push of a button, the anchor can be deployed or retrieved quickly and easily, without the need for strenuous manual labor.

- Increased Safety: Operating an electric windlass from a safe distance minimizes the risk of injury or strain that can occur with manual anchoring methods. This is particularly important in rough conditions or for larger vessels where handling the anchor manually can be dangerous.

- Time Savings: By automating the anchoring process, an electric windlass saves considerable time, allowing boaters to focus on other important tasks or relax during anchoring operations. This is especially helpful for frequent anchoring or when time is of the essence.

- Consistency and Control: With an electric windlass, the operator has greater control over the anchor’s deployment. The device ensures smooth and steady operation, reducing the likelihood of issues such as the anchor becoming tangled or improperly set.

- Reduced Wear and Tear: By removing the physical strain involved in traditional anchoring methods, the wear and tear on both the crew and the boat is minimized. The electric windlass also reduces the mechanical strain on anchor chains and the windlass system itself, contributing to the longevity of the equipment.

Electric Windlass vs. Manual Windlass: A Comparison

When it comes to anchoring systems, there are two primary types: electric and manual windlasses. While both serve the same purpose, each has distinct advantages and disadvantages. Here is a comparison between the two:

| Feature | Electric Windlass | Manual Windlass |

|---|---|---|

| Ease of Use | Very easy to use, operated with a button or switch. | Requires significant physical effort to operate. |

| Speed | Much faster than manual windlasses, as it uses motor power. | Slower operation, dependent on manual effort. |

| Labor Intensity | Minimal physical effort is needed. | Requires considerable physical strength and effort. |

| Maintenance | Requires regular maintenance of the motor and electrical components. | Less complex maintenance, but requires manual labor to ensure optimal function. |

| Cost | Tends to be more expensive due to the motor and electrical components. | More affordable, but lacks the convenience and speed of electric systems. |

How Does an Electric Windlass Enhance Anchoring Efficiency?

The Electric Windlass enhances anchoring efficiency in several ways:

- Quick Operation: The electric windlass allows for faster deployment and retrieval of the anchor, reducing the overall time spent on anchoring procedures. This is especially beneficial in situations where swift anchoring is essential, such as when docking in busy harbors or during emergency situations.

- Improved Precision: With the ability to control the anchor's depth with greater precision, an electric windlass ensures that the anchor is deployed exactly where needed. This precision helps prevent errors such as the anchor dragging or becoming stuck.

- Effortless Operation in Rough Conditions: In adverse weather or sea conditions, using an electric windlass is far more efficient and safer than relying on manual effort. The motor takes care of the heavy lifting, reducing strain on the crew and ensuring the anchor is set without delay.

- Convenience: With an electric windlass, there is no need for crew members to haul up the anchor manually, freeing them to focus on other tasks. The device can be operated from the safety of the cabin or the helm, improving the overall convenience of anchoring.

Frequently Asked Questions (FAQs)

Q1: Can an electric windlass be installed on any boat?

A1: While most boats can benefit from an electric windlass, the size and weight of the vessel will determine the specific windlass model needed. It is important to choose a windlass that suits your boat's size, weight, and anchoring needs.

Q2: How much power does an electric windlass consume?

A2: The power consumption of an electric windlass depends on the motor's specifications and the size of the vessel. On average, electric windlasses can consume between 500W to 2000W depending on the boat size and windlass type.

Q3: Is an electric windlass maintenance-intensive?

A3: Like any mechanical system, an electric windlass requires regular maintenance, including cleaning, lubricating moving parts, and inspecting the motor and electrical components. Routine maintenance will help prolong the windlass's lifespan and ensure smooth operation.

Q4: Can I convert my manual windlass to an electric one?

A4: Yes, it is possible to retrofit an electric motor to a manual windlass system. However, it is important to consult with a professional to ensure compatibility and proper installation.

The Electric Windlass has greatly improved anchoring efficiency by automating the process, reducing physical strain, and increasing safety for boaters. Its ability to perform the task quickly, efficiently, and with precision makes it an invaluable tool for any mariner or boater. Whether you're navigating calm seas or battling rough waters, the electric windlass will make anchoring a smoother, safer, and more efficient task.

English

English  عربى

عربى  中文简体

中文简体