What Are the Noise and Vibration Considerations of an Electric Windlass?

2026.01.16

2026.01.16

Industry News

Industry News

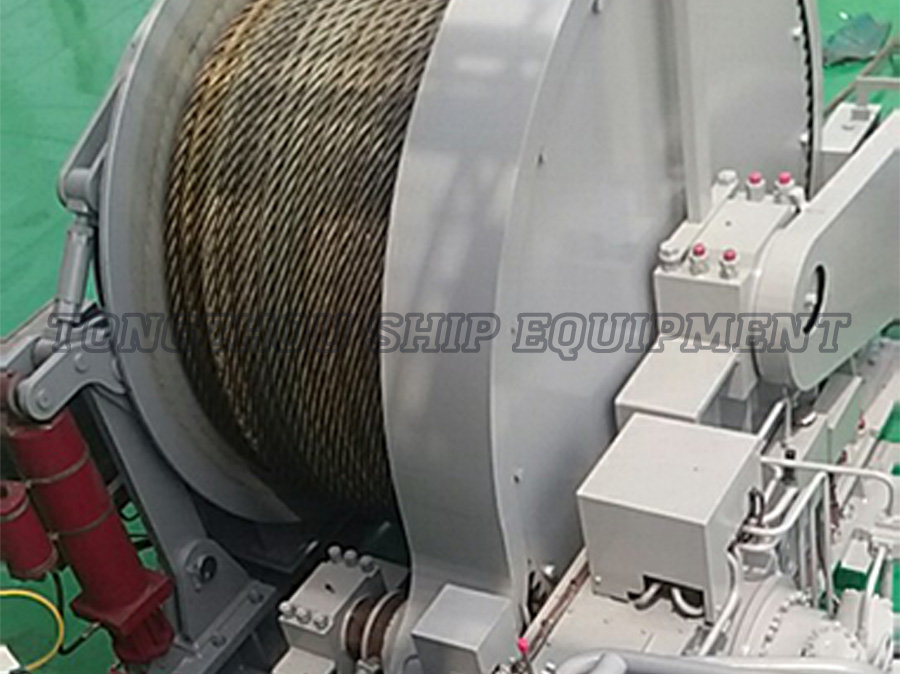

The Electric Windlass is an essential piece of equipment on modern vessels, simplifying the process of anchoring and mooring. However, like any mechanical device, it generates noise and vibration during operation. Understanding these factors is crucial for improving onboard comfort, ensuring equipment longevity, and maintaining safety standards.

Sources of Noise and Vibration in Electric Windlasses

Noise and vibration in an Electric Windlass primarily originate from the following sources:

- Motor Operation: The electric motor generates both mechanical and electromagnetic noise, which can be transmitted through the windlass housing and the boat’s structure.

- Gear Mechanisms: Internal gears can create high-pitched or grinding noises, particularly if the gears are worn, misaligned, or lack proper lubrication.

- Anchor Chain or Rope: The movement of the anchor chain or rope through the windlass can create rattling or clanking sounds, especially under heavy loads.

- Mounting and Hull Interaction: Vibrations can be amplified if the windlass is not securely mounted or if the hull structure resonates at certain frequencies.

Impact of Noise and Vibration

Excessive noise and vibration from an Electric Windlass can affect multiple aspects of boating:

- Passenger Comfort: Persistent vibration or loud operation can lead to discomfort for crew and passengers, particularly during long voyages.

- Equipment Longevity: High levels of vibration may accelerate wear and tear on motor components, gears, and bearings, potentially leading to premature failure.

- Structural Stress: Vibrations transmitted to the hull can cause fatigue over time, impacting structural integrity and safety.

Reducing Noise and Vibration in Electric Windlasses

Manufacturers and marine engineers employ several strategies to minimize noise and vibration in Electric Windlass systems:

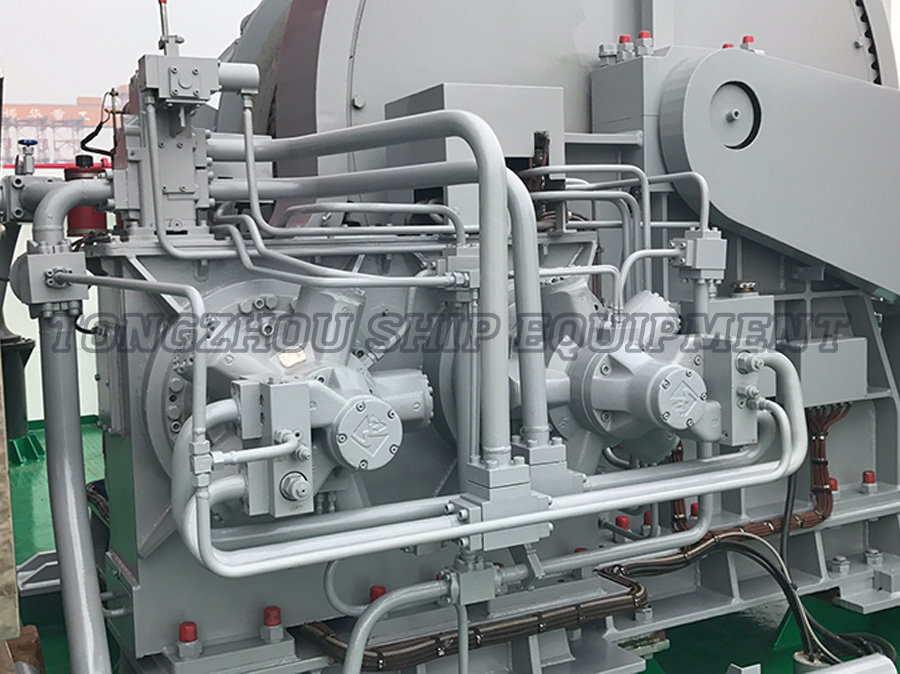

1. Motor Isolation and Mounting

Installing vibration-damping mounts or pads between the windlass and the deck helps isolate motor vibrations from the hull, significantly reducing noise transmission.

2. Gear Quality and Lubrication

High-quality precision gears, combined with appropriate lubrication, reduce friction and gear noise. Regular maintenance ensures that gears remain in optimal condition.

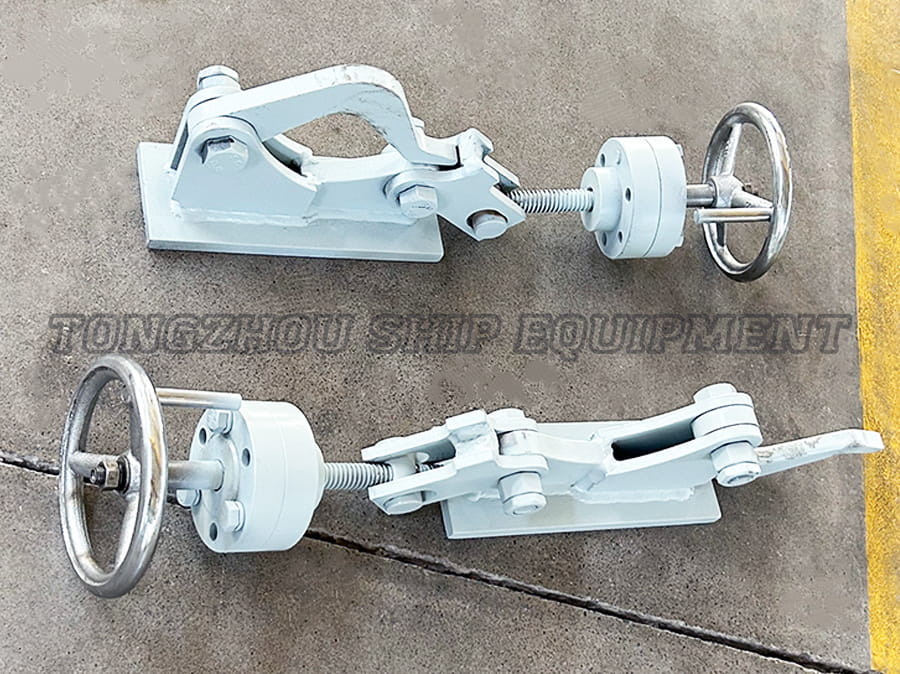

3. Chain Management

Using chain stoppers, tensioners, or rubber pads in the chain locker can minimize clanking sounds when the anchor is deployed or retrieved.

4. Electrical Noise Suppression

Installing filters or noise suppression devices on the electric motor circuits can reduce electromagnetic noise that contributes to operational hums or buzzes.

5. Hull Reinforcement

Strategically reinforcing the deck or hull area around the windlass mounting point can reduce resonance, absorbing vibrations and preventing structural amplification.

Comparison with Manual and Hydraulic Windlasses

When assessing noise and vibration, it is useful to compare Electric Windlass systems with manual and hydraulic alternatives:

- Manual Windlasses: Typically produce minimal noise and vibration because there is no motorized operation. However, they require physical effort, which can be impractical for large anchors.

- Hydraulic Windlasses: Offer smoother operation and lower vibration levels compared to some electric models. However, hydraulic systems may generate fluid noise and require additional maintenance.

- Electric Windlasses: Provide the convenience of push-button operation but need careful design and installation to minimize noise and vibration.

Maintenance Tips for Noise and Vibration Control

Regular maintenance is crucial for controlling noise and vibration in an Electric Windlass:

- Inspect and lubricate gears and bearings at recommended intervals.

- Check motor mounts and fasteners for tightness and wear.

- Ensure the anchor chain is free from corrosion and twists.

- Clean the windlass housing and components to prevent debris from increasing vibration or noise.

Frequently Asked Questions (FAQ)

Q1: Why is my electric windlass making a rattling noise?

A rattling noise is often caused by loose anchor chain links, misaligned gears, or worn bearings. Regular inspection and proper lubrication can resolve most issues.

Q2: Can vibration damage my boat hull?

Yes, prolonged and excessive vibration can cause fatigue in the hull structure, especially in older vessels. Using vibration-damping mounts and reinforcing the deck can help mitigate this risk.

Q3: Are all electric windlasses noisy?

Not all Electric Windlass models produce significant noise. Quality models with precision gears, proper motor isolation, and correct installation are typically quiet and smooth in operation.

Q4: How often should I maintain the windlass to control noise?

Maintenance frequency depends on usage, but inspecting gears, bearings, and mounts every 3–6 months is recommended for recreational vessels, and more frequently for commercial use.

Conclusion

Noise and vibration are important considerations when installing or operating an Electric Windlass. By understanding the sources of these issues and implementing proper maintenance, mounting, and design strategies, boat owners can enjoy a quieter, smoother anchoring experience while protecting both equipment and hull integrity. Choosing a high-quality windlass and following best practices ensures reliable operation with minimal disturbance.

English

English  عربى

عربى  中文简体

中文简体