What Are the Main Components of an Electric Windlass?

2026.01.09

2026.01.09

Industry News

Industry News

An Electric Windlass is a vital piece of equipment for modern boating, providing automated anchor handling and enhancing both safety and convenience. Understanding its main components is essential for operators, marine engineers, and boating enthusiasts who aim to maintain efficiency and reliability while reducing manual effort.

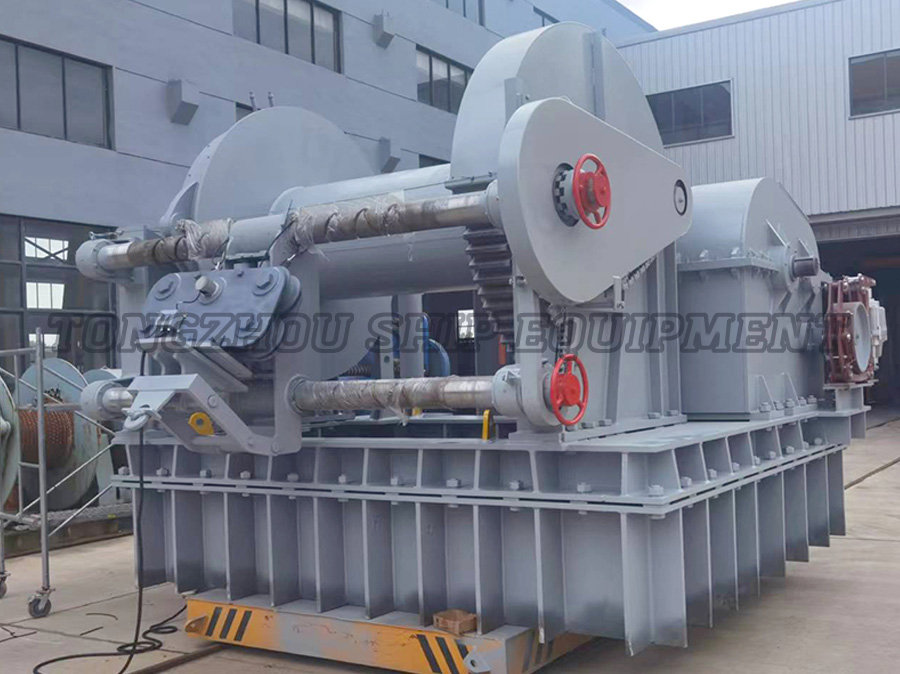

Main Components of an Electric Windlass

An Electric Windlass consists of several key components that work together to control the anchor chain or rope. Each part plays a critical role in ensuring smooth operation and long-term durability.

1. Motor

The motor is the heart of the Electric Windlass. It provides the mechanical power required to lift or lower the anchor. There are two main types of motors:

- AC Motors: Powered by alternating current, typically used in larger vessels where shore power is available. They are known for smooth operation and high torque.

- DC Motors: Powered by direct current, usually from the vessel’s battery system. DC motors are common in smaller boats due to portability and independence from shore power.

Comparison: DC motors are more flexible for smaller vessels but may require careful monitoring of battery life, while AC motors offer consistent performance with higher power demands.

2. Gearbox

The gearbox connects directly to the motor and adjusts the speed and torque applied to the anchor chain. Key features include:

- Reduction Ratios: Determines how fast the anchor is raised or lowered. Higher reduction ratios provide more torque but slower speed.

- Durable Gears: Typically made from marine-grade metals to resist corrosion and wear.

Comparison: Worm gear designs are common for compact windlasses, providing high torque and self-locking properties, while spur gears are often used for larger, high-capacity systems.

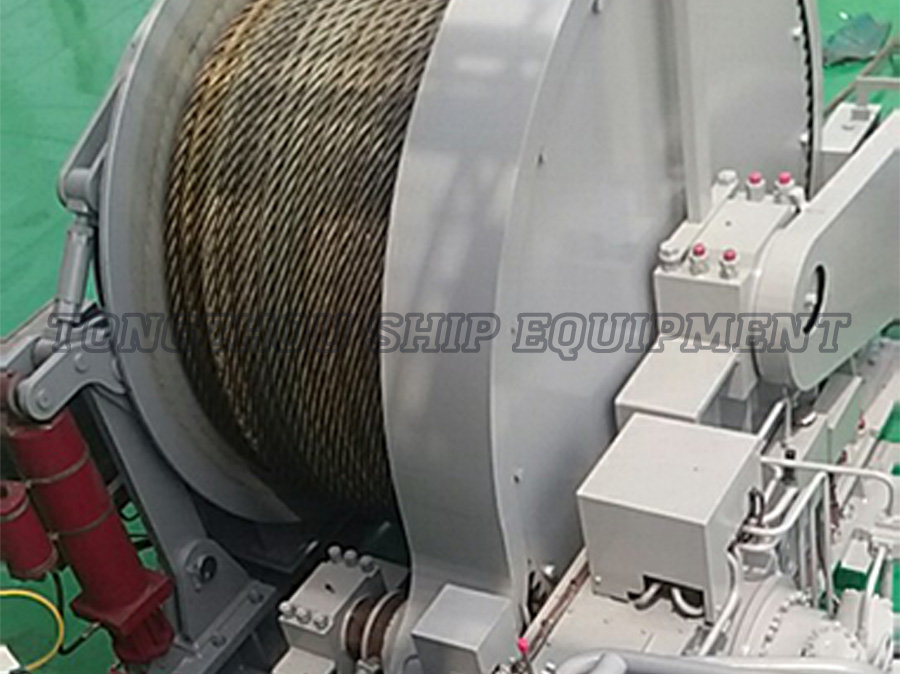

3. Gypsy (Chain Wheel)

The gypsy, also known as the chain wheel, is the part that grips and moves the anchor chain. It comes in various sizes and designs depending on the chain link type:

- Standard Gypsy: Matches the size of the anchor chain and ensures secure handling.

- Multi-Link Gypsy: Can accommodate different chain sizes, providing versatility for boats with multiple anchor setups.

Comparison: Single-size gypsies are simpler and more efficient for one type of chain, while multi-link gypsies offer flexibility but may require more maintenance.

4. Deck or Drum Unit

The deck or drum unit is the visible part of the windlass mounted on the boat's deck. It houses the gypsy and provides the anchoring interface. Key elements include:

- Top Cap: Protects internal components from water and debris.

- Clutch Mechanism: Engages or disengages the gypsy from the motor to allow freewheel operation.

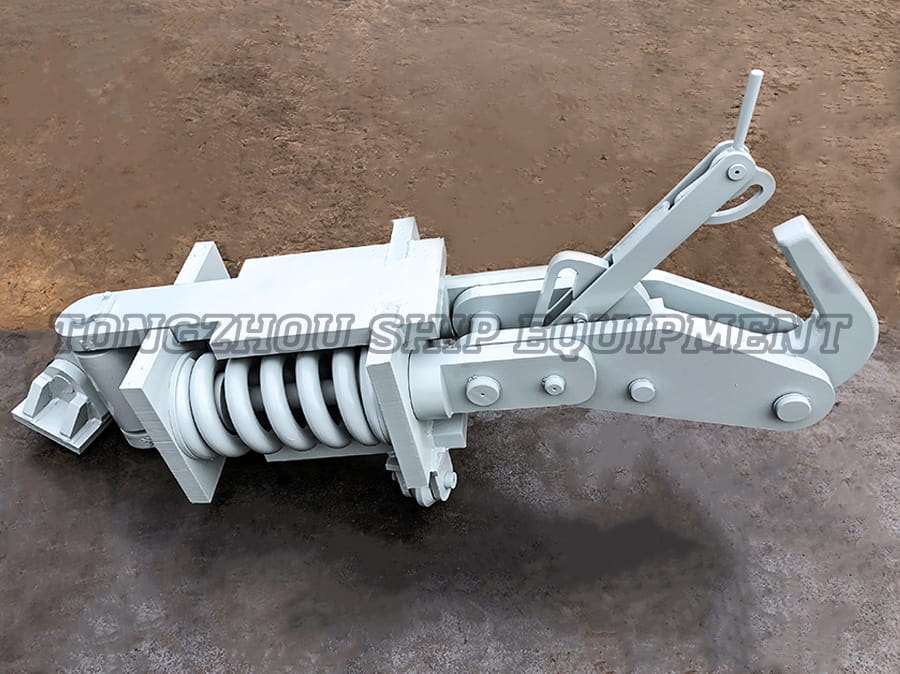

5. Brake and Clutch System

A reliable Electric Windlass must have a strong brake and clutch system to control the anchor's descent and hold it securely when stationary. Key points include:

- Mechanical Brakes: Often spring-loaded or friction-based to hold the load.

- Clutch Adjustment: Allows the user to fine-tune tension, enabling controlled raising and lowering of the anchor.

Comparison: Mechanical brakes provide reliable load-holding even in power loss situations, while hydraulic brakes may offer smoother operation but increase system complexity.

6. Chain Stopper

The chain stopper is an additional safety feature that secures the anchor chain independently of the windlass motor. It prevents undue strain on the motor and gearbox when the anchor is deployed for long periods.

7. Electrical Controls

Modern Electric Windlass systems include sophisticated electrical controls for enhanced usability:

- Remote Switches: Allow the operator to raise or lower the anchor from the helm or deck.

- Foot Pedals: Offer hands-free operation for quick adjustments.

- Integrated Safety Features: Include circuit breakers, thermal overload protection, and limit switches to prevent overextension or damage.

8. Anchor Chain and Rope Integration

The windlass works closely with the anchor chain and, in some systems, a rope/chain combination. Compatibility with the chain diameter and material ensures smooth operation and prevents slippage or jamming.

Material Considerations

Durability and resistance to corrosion are crucial for all Electric Windlass components. Common materials include:

- Marine-Grade Stainless Steel: Highly resistant to saltwater corrosion, often used for gypsies, drums, and deck fittings.

- Bronze or Aluminum Alloys: Used in gearboxes and motors to reduce weight while maintaining strength.

- High-Strength Composites: Sometimes used in low-load or recreational windlasses for lightweight performance.

Comparison with Manual Windlasses

Unlike manual windlasses, electric versions provide:

- Ease of Operation: Reduced physical effort, especially for large anchors.

- Speed Control: Precise raising and lowering of the anchor.

- Safety: Integrated brakes and electrical controls reduce the risk of accidents.

However, electric windlasses require maintenance of the motor, gearbox, and electrical system, whereas manual windlasses are simpler but physically demanding.

Installation and Maintenance Tips

- Ensure proper alignment of the motor and gearbox to avoid undue wear.

- Regularly inspect the gypsy and clutch for signs of corrosion or slippage.

- Keep electrical connections clean and protected from moisture.

- Use a chain stopper when the anchor is deployed for extended periods.

Frequently Asked Questions (FAQ)

Q1: Can an electric windlass handle different types of anchors?

Yes, but it is essential to match the windlass capacity and gypsy design to the specific anchor type and chain size to ensure smooth operation.

Q2: How long does an electric windlass last?

With proper maintenance, including lubrication, cleaning, and electrical inspections, a high-quality electric windlass can last 10–20 years.

Q3: Is it safe to use an electric windlass in rough seas?

Yes, especially models with mechanical brakes and clutch systems. Operators should ensure proper engagement and avoid sudden loads beyond rated capacity.

Q4: What is the difference between DC and AC electric windlasses?

DC windlasses are battery-powered, suitable for small to medium boats, while AC windlasses require shore or generator power and are common in larger vessels. AC systems provide more consistent power for heavy-duty anchors.

Q5: Can an electric windlass be used with synthetic ropes?

Yes, many modern windlasses can handle rope or rope/chain combinations. It is important to use a compatible gypsy and follow the manufacturer’s recommendations to prevent slipping or damage.

Understanding the main components of an Electric Windlass is crucial for ensuring safe and efficient anchor handling. From the motor and gearbox to the gypsy, clutch, and electrical controls, each part contributes to a reliable system that simplifies anchoring tasks. Regular maintenance, proper installation, and knowledge of material compatibility enhance performance and prolong the life of the windlass, making it an indispensable tool for modern boating.

English

English  عربى

عربى  中文简体

中文简体