What is an electric windlass, and what role does it play in a ship?

2026.01.04

2026.01.04

Industry News

Industry News

The Electric Windlass has become an indispensable piece of equipment in modern maritime operations. Designed to simplify the deployment and retrieval of anchors, it enhances safety, efficiency, and overall vessel management. Understanding its components, functionality, and advantages is essential for shipowners, sailors, and marine engineers alike.

What is an Electric Windlass?

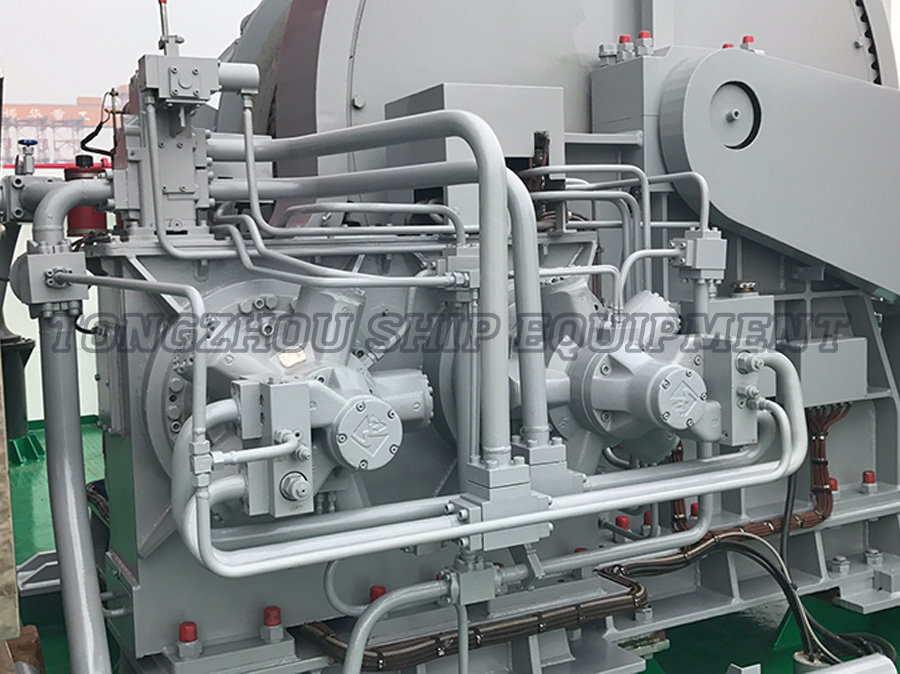

An Electric Windlass is a mechanical device installed on a ship or boat that uses electric power to raise and lower the anchor. Unlike traditional manual windlasses, which rely on human strength or hydraulic systems, an electric windlass provides a more convenient and efficient solution for anchor handling.

Typically, an electric windlass consists of several key components:

- Motor: Provides the necessary power to drive the windlass drum or gypsy.

- Gypsy/Drum: A wheel that grips the anchor chain or rope and facilitates raising or lowering.

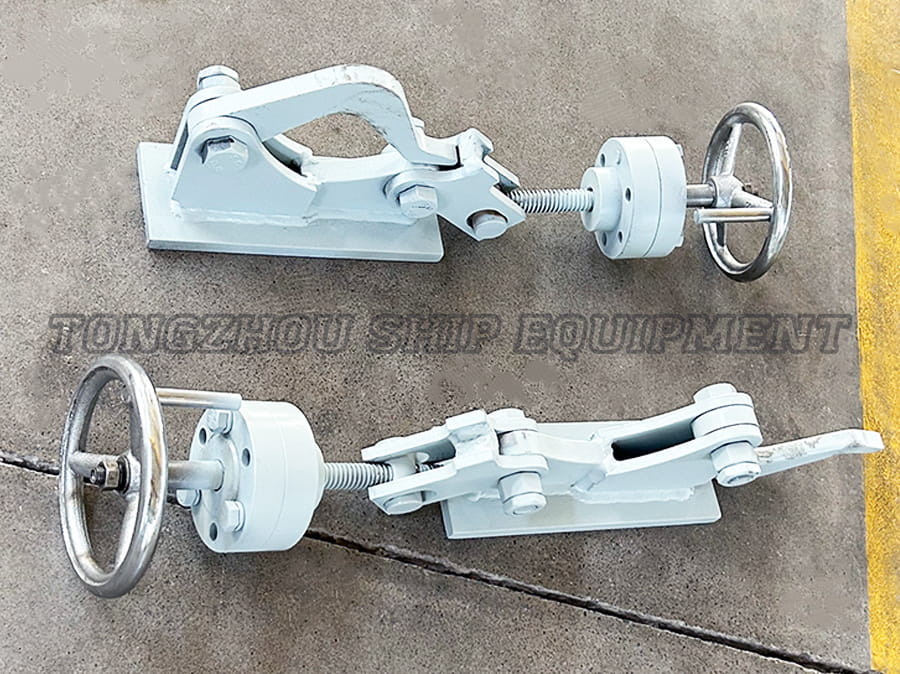

- Brake system: Ensures controlled movement of the anchor and prevents accidental free-fall.

- Foot switches or remote control: Allows operators to control the windlass safely from the deck or cockpit.

How Does an Electric Windlass Work?

The operation of an Electric Windlass is relatively straightforward. When the anchor needs to be deployed, the motor engages, turning the gypsy and lowering the anchor chain into the water. Conversely, when the anchor is retrieved, the motor reverses, pulling the anchor and chain back onto the deck. Modern windlasses often include safety features such as automatic brakes, overload protection, and chain stoppers to prevent accidents.

Types of Electric Windlasses

Electric windlasses come in various types depending on the size of the vessel, anchor weight, and intended use:

- Vertical Electric Windlass: The motor is mounted vertically below deck, offering more torque for heavier anchors.

- Horizontal Electric Windlass: Motor is mounted horizontally, usually on smaller vessels, providing easier installation.

- Portable Electric Windlass: Compact and lightweight, designed for smaller boats or temporary installations.

Advantages of Using an Electric Windlass

Compared to manual or hydraulic systems, an Electric Windlass offers multiple advantages:

- Ease of Operation: Simplifies anchor handling, reducing physical strain on the crew.

- Time Efficiency: Rapid deployment and retrieval of anchors save valuable time during docking or emergency situations.

- Enhanced Safety: Reduces the risk of accidents caused by heavy manual lifting or chain slippage.

- Consistent Performance: Electric motors deliver steady torque, ensuring smooth and reliable operation.

Electric vs. Manual Windlasses

Manual windlasses have been used for centuries and rely on human power, making them simple but labor-intensive. While manual systems are inexpensive and require minimal maintenance, they are less efficient, especially for larger vessels. In contrast, Electric Windlasses provide significant advantages in automation, speed, and crew safety, making them the preferred choice for modern yachts, commercial ships, and even small pleasure boats.

Applications of Electric Windlasses in Shipping

The use of Electric Windlass extends beyond recreational vessels. It is widely adopted in commercial shipping, fishing boats, and offshore operations:

- Yachts and Leisure Boats: Enables solo or small crews to manage anchors efficiently.

- Commercial Vessels: Ensures quick anchoring in harbors, ports, and emergency situations.

- Fishing and Research Ships: Facilitates rapid deployment of nets, traps, or scientific instruments.

Materials and Build Quality

High-quality Electric Windlasses are typically constructed from corrosion-resistant materials such as marine-grade stainless steel, aluminum, or bronze. These materials ensure durability against harsh saltwater conditions. Components like gypsies and drums often have hardened surfaces to resist wear and extend the service life of the equipment.

Installation and Maintenance Tips

Proper installation is crucial for optimal performance of an Electric Windlass. Consider the following guidelines:

- Mount the windlass on a reinforced deck area to withstand anchor weight.

- Ensure the electric motor and wiring meet marine-grade standards.

- Use appropriate chain stoppers and cleats to secure the anchor when not in use.

- Regularly inspect moving parts, lubricate bearings, and check electrical connections.

Routine maintenance, including cleaning, lubrication, and periodic inspection of the brake system, ensures long-term reliability and safety.

Comparing Electric Windlass Brands

Several manufacturers provide reliable electric windlasses, each with unique features. Popular brands focus on motor power, durability, and ease of installation. While cost can vary significantly, investing in a high-quality windlass reduces maintenance costs and increases operational safety.

Frequently Asked Questions (FAQ)

1. Can an Electric Windlass be used on small boats?

Yes, smaller electric windlasses are designed for small yachts and recreational boats, offering sufficient power for light anchors.

2. How much power does an Electric Windlass require?

Most windlasses operate on 12V or 24V DC systems, but larger commercial windlasses may require higher voltage or specialized electrical setups.

3. Is it safe to leave the anchor chain in water with an electric windlass?

While electric windlasses have braking systems, it is recommended to use a chain stopper or cleat to secure the anchor when left unattended.

4. How often should maintenance be performed?

Routine maintenance should occur every 3–6 months, depending on frequency of use and exposure to saltwater conditions.

5. What are the alternatives to Electric Windlasses?

Alternatives include manual windlasses and hydraulic systems. Manual windlasses are less expensive but labor-intensive, while hydraulic windlasses offer high torque but require complex plumbing and maintenance.

The Electric Windlass has transformed anchor handling in modern vessels. By providing efficiency, safety, and ease of operation, it is an essential investment for both recreational and commercial shipping. Understanding its structure, functionality, and maintenance requirements ensures a smoother, safer, and more reliable maritime experience.

English

English  عربى

عربى  中文简体

中文简体